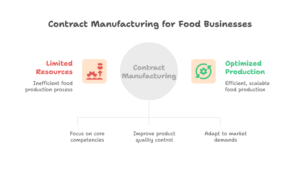

The food industry is very competitive, and businesses feel pressure to adapt and improve their products, services, and processes without compromising on expenses. This can be challenging in such a tough market. So, how can businesses stay relevant and succeed? There is one solution, which is a contract manufacturer in the food sector or third-party food manufacturing.

Companies avoid the capital-intensive costs of building facilities, investing in equipment, and hiring labor—allowing funds to be redirected to R&D, marketing, or sales. Private-label retail brands often earn up to 35% profits, compared to roughly 26% for national brands—boosting retailer margins in a high-pressure market for modern food products.

Now let’s get into the main aspects, look at the benefits of outsourced food production or private-label food manufacturers in the food industry, and see how it can make your brand win.

Access to Specialized Expertise and Equipment

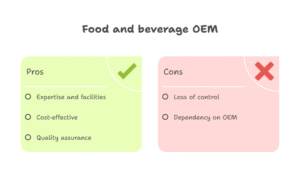

Food and beverage OEM is advantageous because the manufacturers’ physical facilities and expertise are obtained after entering a contract. For a long time, the food industry has used custom food manufacturing to produce various foods. They understand all aspects of food product development, from sourcing the raw stock to processing, packing, and delivering the finished product; they can also ensure that all products match the standard and way of Food Product Innovations.

These manufacturers also purchase equipment and technology that a smaller company may need help to afford the cost of purchasing. If you collaborate with them, your business can benefit from these excellent tools and a wealth of experience to offer your consumers great items for a low initial investment.

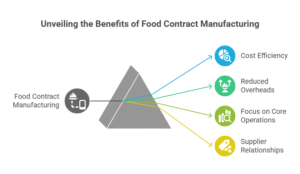

Cost Efficiency and Reduced Overheads

If you opt for food contract manufacturing services, the costs and overhead charges come down a great deal for your business. When you outsource, you avoid incurring additional costs of sourcing equipment, establishing facilities, and recruiting a professional workforce. This way, you can direct your attention and resources to other important segments of your company’s operation, like advertising, innovation, and sales.

Additionally, FMCG contract manufacturing may tend to befriend their suppliers, making acquiring the ingredients at cheaper and affordable prices easier. These savings can then be applied to you, making your products more affordable.

Scalability and Flexibility

This is true, especially in the food industry, where the demand for a particular type of food may fluctuate. Custom food manufacturing allows the company to adjust the capacity needed depending on the market demands. Contract manufacturers adapt well to production fluctuations; this is because you may need more units when you have introduced a new food product in the market, or you may require fewer during off-seasons.

This scalability is especially advantageous for small and medium enterprises needing more capacity to run large production. In comparison, they also need more capacity to control the changes in demand. Using the services of a contract manufacturer allows one to change market requirements quickly without sacrificing the quality of the product and its delivery time.

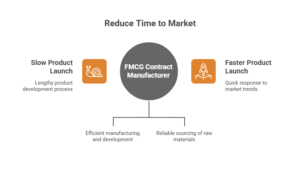

Faster Time to Market

Speed is a critical factor in the food industry, where trends can change rapidly, and consumer preferences evolve quickly. Working with an FMCG contract manufacturer can significantly reduce the time it takes to bring a product from concept to market. These manufacturers have streamlined processes and established supply chains that enable faster production and distribution.

Focus on Core Competencies

Outsourced food production to a contract manufacturer allows your business to focus on its core competencies. Instead of spending time and resources managing the complexities of manufacturing, you can concentrate on areas where you excel, such as product development, marketing, and customer engagement.

Optimised Quality Assurance and Risk Management

This is especially the case for the food industry because the quality and safety of food are important. Food contract manufacturing and beverage contract manufacturing have strong quality control and knowledge of the rules and regulations in the manufacturing area. If you engage the services of a competent contract manufacturer, you will be able to have your products abide by all the pertinent safety and quality standards.

These manufacturers have regular quality control personnel and sophisticated testing laboratories to guarantee the quality of products produced by ensuring the quality of each batch of food products.

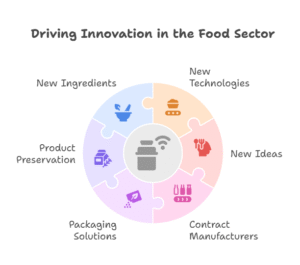

Information Technology, New Technologies, and New Ideas

Competition is stiff in the food sector, thus making it essential for people to come up with new ideas. Contract manufacturers look for better ways to enhance and optimize their business today. With the help of a contract manufacturer, your business doesn’t have to invest heavily to obtain such innovations.

As for the new product development concepts, which may be new packaging solutions, different methods of product preservation, or new ingredients, a contract manufacturer can turn them into reality. These kinds of direct access to innovation can make your product distinct from your competitors in the market.

Risk Mitigation

Managing production in-house can be challenging, and risks include equipment failure, supply chain disruption, and labour force shortage. However, these risks can be managed when you outsource your production to a contract manufacturer. Contract manufacturers also have backup strategies to deal with shocks in production to avoid the breakdown of production continuity.

Also, they can handle the various suppliers’ chains and any unforeseeable hitches. Such risks reduce the disruptions companies may face in production, allowing your business to work on strategic development plans without worrying about production hitches.

Sustainability and Environmental Impact

It is worth noting that most contract manufacturers are aware of sustainable manufacturing and observe some values, such as responsible sourcing of ingredients, reduction of wastage, and a small carbon footprint. Such manufacturers need to be approached for use by the business to meet environmental standards and cater to conscious clients.

When you get the services of a contract manufacturing and beverage contract manufacturing that adheres to sustainable practices, your brand will benefit from a good image in the eyes of the consumers, given the increasing conscious push towards environmental conservation worldwide, especially in the food industry. This partnership can also reveal opportunities for new markets since people now prefer products that indicate they are friendly to the environment.

| Benefit | Why It Matters | How It Helps Your Business |

| Cost Savings | Avoid high setup costs, equipment, and staff expenses | Use funds for product innovation, marketing, and growth |

| Scalability & Flexibility | Adjust production based on demand easily | Launch seasonal or trending products quickly |

| Expertise & Technology Access | Get access to advanced machinery and skilled teams | Create high-quality food products without major investment |

| Faster Time to Market | Ready infrastructure speeds up production | Bring products to the shelf before competitors |

| Focus on Core Business | Outsource the complex production work | Spend more time on sales, branding, and customer relationships |

| Risk Management | Handle supply chain issues, labor shortages, or production glitches | Ensure smooth and continuous product delivery |

| Quality & Food Safety | Built-in quality checks, lab testing, and compliance with regulations | Meet standards like FSSAI, BRCGS, or ISO with confidence |

| Sustainable Production | Eco-friendly manufacturing, reduced waste, and lower carbon footprint | Build a greener brand image and appeal to conscious customers |

| New Product Development | Access R&D experts and food scientists through food and beverage OEMs | Launch innovative formats in snacks, beverages, sauces, and more |

| Growth Opportunities | Private-label brands can earn up to 35% profit, compared to 26% for national brands (Nielsen) | Boost your margins and build loyal customer bases under your own label. |

Ready to scale smarter and innovate faster?

Partnering with a contract manufacturer in the food sector offers numerous benefits, from cost savings and scalability to access to expertise and innovation. By outsourcing production, your business can focus on core competencies, reduce risks, and improve product quality, all while responding swiftly to market demands.

Whether you are a start-up looking to bring a new food product to market or an established company aiming to optimize your supply chain, working with a contract manufacturer can provide the flexibility and resources needed to succeed in the competitive food industry. Consider exploring this partnership to unlock new growth opportunities and drive your business forward.

Partner with Foodsure—your trusted ally in food contract manufacturing.

If you are looking for the best contract manufacturing company, contact Foodsure now. At Foodsure, we are at the forefront of food contract manufacturing services, continuously innovating to meet changing consumer needs. We help food manufacturers, retailers, and consumers adapt and thrive in the evolving food landscape by applying these trends.

Book your free consultation with us now at +91 8130404757.