Food R&D (research and development) is changing in many ways. Earlier, food labs used to depend on manual work, trial-and-error testing, and making changes step by step. But now, new technologies like AI (Artificial Intelligence), Robotics, and IoT (Internet of Things) are making food labs smarter and faster. These technologies, like AI in food R&D labs, help to create better products, improve quality, and save time and money.

You are either making a healthy drink, a plant-based snack, or a natural sauce; these technologies in the food R&D labs can give you a big advantage. In this blog, we’ll look at how AI, robotics, and IoT are being used in modern food labs and how they are changing the future of the food industry.

2025 Market Report Of AI, Robotics, And IoT In Food R&D Labs

Market Overview

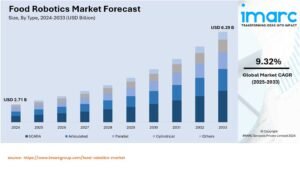

The implementation of AI, Robotics, and IoT technologies in food R&D labs is witnessing a major growth in 2025. The food robotics market is currently valued between $1.4 billion and $2.9 billion, with estimates to reach approximately $4.5 billion by 2029, growing at a CAGR of around 12%. This growth is because of the increasing automation needs, strict food safety regulations, and rising consumer demand for transparency and quality of food products. (Source)

Key Market Drivers

- Labor Shortages: The food industry faces several workforce challenges that force the adoption of robotics and AI to automate labor-intensive tasks like packaging and inspection of the quality of food products.

- Food Safety and Compliance: Increased regulatory requirements and consumer focus on food safety are pushing the use of AI systems and IoT solutions.

- Efficiency in Operations: Robotics and IoT helped to improve the complete output, reduction in waste, and provide real-time monitoring, which helps to increase productivity and sustainability in food R&D labs. (Source)

Regional Insights

- Europe: Holds the largest market share in 2025, supported by advanced food processing infrastructure and early technology adoption.

- North America: Exhibits the fastest growth rate, driven by substantial investments in automation and digital transformation.

- India: Emerging as a high-growth market, with the food robotics sector expected to nearly double from $88.6 million in 2024 to $198 million by 2033. (Source)

AI In Food R&D Labs

AI in food R&D labs helps the food technologists to decide which ingredients to use and how much of each one is needed. Instead of guessing, AI uses data from traditional recipes, consumer feedback, and nutritional targets to find the best combinations.

Like, if a company wants to make a sugar-free cookie, AI in food R&D labs can look at data from other low-sugar snacks and suggest natural sweeteners and fiber types that give the same taste and texture.

AI in food R&D labs is also used for predicting how a product will taste or feel in the mouth. If a protein shake is too thick or too bitter, AI in food formulation R&D labs can suggest changes in ingredients that might fix it, before the food recipe formulation team even makes a physical sample.

In clean-label product development (where brands want to avoid artificial ingredients), AI helps find natural replacements for things like preservatives or synthetic colors.

Robotics In Food R&D Labs

Robotics in food R&D labs is like extra hands that never make mistakes. They are used for jobs that require high accuracy, especially when small ingredients or complex mixtures are involved.

One major use of robotics in food R&D labs is the measurement of ingredients. Robots can weigh even the tiniest amount of an ingredient, down to milligrams, much more accurately than humans.

Robotics in food formulation R&D labs is also great for preparing samples. For example:

- Filling small test bottles

- Mixing formulas the same way every time

- Cleaning up equipment between tests

This saves the time of the food scientists and makes sure that the results are consistent.

Some advanced food formulation R&D labs also use robotic cooking machines. These simulate baking, frying, or fermenting with perfect timing and temperature control. This helps R&D teams test how a recipe behaves during actual processing, just like it would in a factory.

IoT In Food R&D Labs

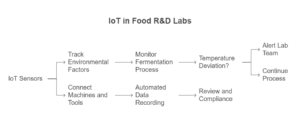

IoT stands for Internet of Things, which means smart devices that collect and share data in real time. IoT sensors in food R&D labs are used to track temperature, humidity, pH (acidity), and light exposure. All of these affect food texture, color, shelf life, and safety.

For instance, if a yogurt sample is being fermented, an IoT sensor can monitor the exact temperature. If it goes too high or too low, the system alerts the lab team or adjusts it automatically. This makes sure the probiotic bacteria grow correctly.

Another benefit of IoT in food formulation labs is that it connects all machines and lab tools. So if a researcher runs 10 different tests, all the data is automatically recorded, organized, and ready to review. This is helpful for both speed and compliance, especially when companies need to follow food safety rules or track every step for quality control.

Latest Update: How Food R&D Is Cooking Up The Next Big Thing

Collaboration Of AI, Robotics, And IoT In Food R&D Labs

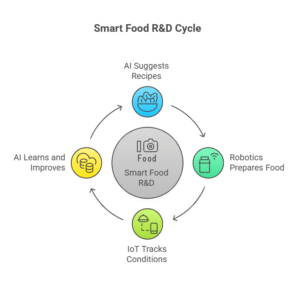

When all three technologies, AI, Robotics, and IoT, are connected, it is called a smart food lab. These labs are made to move faster and make better decisions with less manual work. The smart food R&D labs work as:

- AI suggests a few food recipe formulation options based on health goals and taste preferences.

- Robotics prepares those food recipes with perfect accuracy.

- IoT sensors track everything during cooking or storage, like heat, moisture, or pH.

- The results go back to the AI system, which learns and improves the next batch.

This cycle continues until the best version of the food recipe development is found. This process can save weeks or even months in food product development.

Some labs even use digital twins, which are virtual copies of products. With a digital twin, the team can test how a snack or drink will perform over a longer time without making the actual food recipe product. It’s like doing science inside a computer.

Real-Time Applications Of AI, Robotics, and IoT Technologies

Let’s look at real examples where smart food technologies are already working:

1. Functional Beverages

- AI helps match vitamins, herbs, or minerals based on their health benefits.

- Robotics measures tiny amounts of active ingredients.

- IoT tracks shelf stability, sedimentation, and pH changes.

2. Plant-Based Meats

- AI suggests the best texture and fat levels.

- Robotics matches real meat cooking (like grilling or baking).

- IoT helps control moisture and fiber levels during extrusion.

3. Customized Nutrition

- AI generates food recipes based on individual health goals.

- Robotics prepares custom supplement sachets.

- IoT sensors track freshness during packaging and delivery.

🎯 Need Help with AI, Robotics, and IoT in Food R&D Labs ?

Talk to our formulation team directly via call or WhatsApp. No waiting. No spam.

What To Keep In Mind When Using AI, Robotics & IoT Tools

While these technologies are exciting, there are a few things companies need to be careful about:

- Cost: Buying smart machines and sensors can be expensive at first.

- Compatibility: Not all machines or software work well together, so the setup must be done smartly.

- Data Quality: AI systems only work well if they get clean, organized data.

- Food Safety Compliance: All steps must still follow government regulations (like FSSAI or FDA rules).

Smart labs are powerful, but they still need food recipe formulation expert teams to use them the right way.

Read More Information: Food Recipe Formulation Using AI

In Summary

AI, Robotics, and IoT in food R&D labs are helping food companies move faster, reduce waste, and create better products. Whether it’s a plant-based burger, a zero-sugar drink, or a functional snack bar, smart food formulation labs can make the journey from idea to launch smoother and quicker. Using these three technologies together can help food brands to get updated with new trends, reduce guesswork, and meet the health and quality expectations of today’s consumers.

Want to build a smart R&D process for your next big food product? Let’s talk about how to set up a future-ready food lab with AI, robotics, and IoT solutions that actually work. Call us now on +91 8130404757.

FAQs

Why are AI, robotics, and IoT transforming food R&D labs?

These technologies power automation in food R&D labs, enabling smart experimentation, real-time data from IoT sensors, and robotic precision in ingredient handling. By combining AI analysis with robotics and IoT, labs can innovate faster, reduce human error, and ensure consistent results in product formulation.

How do these technologies enhance quality control in food product development?

AI-powered computer vision and sensors detect defects, anomalies, and contamination faster and more reliably than human inspection. Meanwhile, IoT devices continuously monitor conditions like temperature or humidity, ensuring every batch meets high safety and consistency standards.

What operational benefits do food R&D labs gain from implementing AI, robotics, and IoT?

Implementing these systems drives significant gains: reduced labor costs, minimized waste via AI-optimized processes, and enhanced efficiency through continuous, precise automation. Such enhancements help R&D efforts scale up, cut expenses, and accelerate time-to-market for new food products.