Food hygiene is the full chain of practices that ensure the safety and quality of the food we eat — from handling raw ingredients to production, packaging, and delivery to consumers. This guide explains what food hygiene is, why it matters, the main standards, practical practices, and how Food Product Development and food businesses can stay compliant and safe.

Why Ask “What Is Food Hygiene?” — And Why It Matters Today

Food hygiene is more than just cleaning — it’s a system that protects consumers, maintains food quality, and keeps your business compliant with regulations. Poor hygiene can cause foodborne illnesses, damage your brand, and even lead to fines or closure.

As the food industry grows and consumers demand safer, higher-quality, and sustainable products, understanding food hygiene helps businesses, startups, and kitchens create safe products, reduce waste, and gain customer trust.

Regulators like FSSAI require food businesses to implement Good Hygiene Practices (GHP) and a Food Safety Management System to prevent contamination. Following proper hygiene practices ensures your food is safe from production to the plate.

Want to optimise your Food Business? Request a free consultation!

Explore Our Exclusive Food Product Development

Important Updates: Innovations in Food Industry

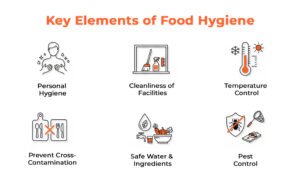

A Simple Breakdown: Key Elements of Food Hygiene

1. Personal Hygiene

- Wash hands thoroughly before handling food and after breaks

- Wear clean protective clothing like aprons, caps, and gloves

- Keep nails short and clean

- Cover cuts with waterproof dressings

- Staff with fever, diarrhea, or vomiting must not handle food

2. Cleanliness of Facilities

- Clean surfaces before and after food prep

- Use food-safe sanitizers

- Maintain documented cleaning schedules

3. Temperature Control

Temperature management is crucial to prevent pathogen growth:

- Cold foods: 0°C–5°C

- Hot foods: 60°C and above

- Danger zone: 5°C–60°C — minimize food exposure in this range

Example Temperature Log:

| Food Item | Storage Temp (°C) | Checked By | Time |

|---|---|---|---|

Milk |

4 |

John |

09:00 |

Cooked rice |

65 |

Sara |

13:30 |

Vegetables |

3 |

Mike |

11:15 |

4. Prevent Cross-Contamination

- Keep raw and cooked foods separate

- Use clean utensils and cutting boards for each task

- Avoid mixing allergens with non-allergens

5. Safe Water & Ingredients

- Only potable water and approved food ingredients

- Check suppliers and ingredient quality regularly

6. Pest Control

- Regular inspections and pest-proofing of facilities

- Proper waste management and covered bins

Food Hygiene Standards: FSSAI & International Practices

| Standard / Requirement | What It Covers |

|---|---|

Good Hygiene Practices (GHP) |

Cleanliness, personal behavior, and sanitation in food handling |

HACCP Implementation |

Identifying hazards and controlling critical points in production |

Documentation |

Records of cleaning, temperature logs, pest control, and staff training |

Facility Design |

Separate zones for raw and cooked foods, handwashing stations, ventilation |

Daily Food Hygiene Checklist

Here is Latest Food Hygiene Checklist:

- Clean and sanitize all food contact surfaces

- Wash hands thoroughly before handling food

- Wear protective clothing (hair nets, gloves, aprons)

- Clean all utensils and equipment before reuse

- Maintain temperature logs for cold and hot foods

- Store raw foods below cooked or ready-to-eat foods

- Cover and empty waste bins regularly

- Conduct regular pest control checks

- Assign responsibility for each task to staff members

Hygiene in Food Packaging and Labelling

Factors of Hygiene in Food Packaging and Labelling:

- Use food-grade, non-toxic packaging

- Protect against moisture and pests

- Include accurate labels with ingredients, allergens, batch number, and dates

Learn more about: Food Packaging and Labelling Regulations

Labelling Essentials

Here are Some Labelling Essentials

- Product name

- Ingredient list in descending order

- Allergen declaration

- Batch number, production and expiry dates

- Veg / Non-veg symbol

Cleaning & Sanitation Procedures

Here are Some Procedures:

- Remove visible waste

- Wash area with detergent

- Rinse with clean water

- Apply food-safe sanitizer

- Dry with a clean cloth

- Document cleaning schedules weekly

Food Hygiene in Food Production Facilities

Facility Layout Tips

Here are Some Tips:

- Separate raw and ready-to-eat areas

- Dedicated handwashing stations

- Easy-to-clean floors and walls

- Adequate ventilation

Equipment Hygiene

Here are Common Factors of Equipment Hygiene:

- Clean before and after use

- Follow manufacturer guidelines

- Regular maintenance to prevent contamination

Training & Certification for Staff

Here are Some Training & Certification for Staff:

- Handwashing and personal hygiene

- Temperature monitoring

- Cleaning chemical use

- Proper food storage and rotation

- Contamination risk identification

Certifications like FoSTaC from FSSAI improve staff knowledge and credibility.

You May Also Like: What is Food Production? Complete Overview

Common Food Hygiene Risks

Here are Some Food Hygiene Risks:

- Poor handwashing

- Untidy preparation areas

- Improper storage temperatures

- Pest infestations

- Ineffective waste management

Solution: Regular audits and surprise inspections.

FSSAI Hygiene Rating Scheme

FSSAI Hygiene Rating Scheme Factors:

- Obtain FSSAI license

- Train Food Safety Supervisor

- Pass hygiene audit by authorized agency

- Display hygiene rating certificate for customers

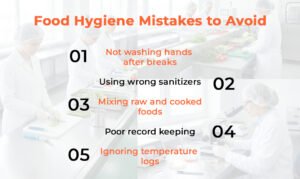

Food Hygiene Mistakes to Avoid

Here are Some Mistakes to Avoid:

- Not washing hands after breaks

- Using wrong sanitizers

- Mixing raw and cooked foods

- Poor record keeping

- Ignoring temperature logs

Example Hygiene SOP for Food Businesses

| Task | Frequency | Responsible |

|---|---|---|

Handwashing checks |

Every shift |

Supervisor |

Surface cleaning |

After each batch |

Food handler |

Waste removal |

Twice daily |

Cleaning staff |

Temperature log update |

Every 2 hours |

Floor manager |

How Food Hygiene Connects to Food Product Development & Business Success

Food hygiene impacts product quality, shelf life, and customer trust. Proper hygiene practices during Food Product Development ensure the final product is safe, scalable, and regulatory-compliant.

- Concept & recipe creation

- Hygiene-conscious pilot production

- Packaging & labelling with proper standards

- Full-scale production with continuous hygiene monitoring

- Distribution & retail with safe handling

Suggested Read: New Food Business Ideas (2026)

Final Takeaways — Why Food Hygiene Matters

Here are Some Final Takeaways:

- Reduce contamination risks

- Improve product quality

- Comply with food safety regulations

- Build customer confidence

- Ensure long-term business success

Get Expert Food Hygiene Consultation

Keeping your food safe and your business compliant is easier with expert guidance. Foodsure provides practical food hygiene consultation to help kitchens, restaurants, and food businesses maintain high standards.

Why Choose Foodsure?

Here are Some Benefits:

- Guidance on FSSAI Compliance and hygiene standards

- Customized advice for your food production, packaging, and operations

- Staff training in safe handling, cleaning, and sanitization

- Practical checklists and audits to reduce contamination risks

Partner with Foodsure’s food consultants to ensure your products are safe, your team is trained, and your business stays compliant. Contact us today to improve your food hygiene and quality.

Get Expert Food Hygiene Guidance Today

FAQ’s (Frequently Asked Questions)

Q1: What is food hygiene?

Food hygiene means following practices that keep food safe and clean, like washing hands, cleaning surfaces, storing food properly, and controlling pests. Example: Kitchen staff washing hands before preparing meals.

Q2: Why is food hygiene important for businesses?

It keeps food safe for consumers, avoids fines, and builds trust with customers. Example: A cloud kitchen following FSSAI hygiene rules to maintain safety.

Q3: What are common food hygiene mistakes?

Not washing hands, mixing raw and cooked foods, ignoring temperature logs, or poor record keeping. Example: Storing raw eggs above ready-to-eat cakes can cause contamination.

Q4: How often should cleaning and sanitization be done?

Daily for surfaces, after every batch for equipment, and weekly review of cleaning logs. Example: Dairy plants sanitizing milk tanks after each production.

Q5: What is the danger zone in food storage?

The danger zone is 5°C–60°C, where bacteria grow fast. Keep cold foods below 5°C and hot foods above 60°C. Example: Cooked rice left at room temperature can spoil quickly.

Q6: How can cross-contamination be prevented?

Use separate utensils for raw and cooked foods, store raw items below cooked foods, and clean surfaces properly. Example: Meat stored below salads in the refrigerator.

Q7: Are FSSAI hygiene ratings necessary?

Yes, they show compliance with food hygiene rules and help attract customers. Example: A restaurant displaying a 5-star FSSAI rating gains more trust.

Q8: How does food hygiene affect product development?

Keeping hygiene during recipe testing and pilot production ensures products are safe and can be scaled. Example: Snack makers testing shelf life under clean conditions.

Q9: What personal hygiene measures should staff follow?

Wash hands properly, wear gloves and hairnets, keep nails clean, and avoid handling food when sick. Example: Hotel chefs following handwashing and uniform protocols.

Q10: How often should pest control inspections occur?

Regularly, at least once a month or as local rules require, to prevent contamination. Example: Food factories scheduling professional pest control inspections quarterly.