In beverage manufacturing, chaos rarely starts with formulation failure. It begins with missing instructions, undocumented assumptions, and loosely defined processes. A beverage manufacturing SOP is frequently created late or created superficially once production problems appear.

As long as product volumes remain small, teams compensate manually. Still, once commercial beverage production begins, these undocumented gaps surface as inconsistency, rework, and delayed launches. Deficient SOPs don’t fail immediately; they fail progressively.

Struggling with inconsistent beverage production or SOP gaps?

Why a Beverage Manufacturing SOP Is a Production Control Tool

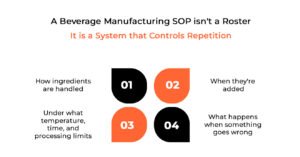

A beverage manufacturing SOP isn’t a roster; it is a system that controls repetition.

A recipe tells:

- What ingredients to use

An SOP defines:

- How ingredients are handled

- When they’re added

- Under what temperature, time, and processing limits

- What happens when something goes wrong

Without this structure, the beverage production SOP becomes operator-driven rather than process-driven, making consistency impossible at scale.

Where SOPs Commonly Break Down in Beverage Manufacturing

| Production Area | What Happens Without Clear SOPs |

| Raw Materials | Variations in quality due to undefined vendor or storage standards |

| Mixing & Blending | Flavour drift caused by incorrect order or timing |

| Thermal Processing | Shelf-life instability due to over- or under-processing |

| Carbonation | Flat or over-pressurised product from undefined parameters |

| Filling & Packaging | Leakage, oxidation, or volume inconsistency |

| Quality Checks | No rejection criteria, leading to delayed issue detection |

| Documentation | Missing batch traceability and audit gaps |

These failures are symptoms of SOP mistakes in beverage manufacturing, not formulation issues.

How Incomplete SOPs Disrupt Beverage Scale-Up

During pilot production, teams rely on experience and memory. During beverage scale-up, this approach collapses.

Without a complete beverage manufacturing SOP:

- An airman’s success can not be replicated

- Production timelines stretch unpredictably

- Costs rise due to rework and wastage

- Manufacturing partners follow assumptions rather than standards

As volumes increase, indeed, minor SOP gaps can lead to operational bottlenecks.

Why SOPs for Beverage Startups Are Often Inadequate

SOP’s for beverage startups are constantly delayed to “move faster”. This creates long-term instability.

Typical startup SOP gaps include:

- No locked formulation version

- undetermined component substitutions

- Missing deviation-handling procedures

- Deficient beverage SOP documentation

Without early SOP discipline, startups struggle to gauge beyond founder-led oversight.

Recommended Read – Beverage Startup Failure Reasons

What Effective Beverage SOP Documentation Must Cover

A functional beverage manufacturing SOP should easily define:

- Recipe and formulation controls

- Raw material specifications and handling

- Processing parameters and limits

- Packaging compatibility and controls

- In-process and final quality checks

- Shelf- life validation logic

- Documentation, traceability, and version control

This structure transforms beverage product SOPs into functional safeguards rather than reactive fixes.

Operational Impact of Incomplete SOPs

Deficient SOPs lead to measurable business consequences:

- Advanced production costs

- Increased batch failures

- Slower non-supervisory readiness

- Reduced distributor confidence

- Delayed market launches

These issues compound quietly until they hang brand credibility.

Related Insights for Beverage Manufacturers

Conclusion

Deficient SOPs don’t produce immediate failure; they produce uncontrollable systems. A strong beverage manufacturing SOP brings predictability, scalability, and responsibility into market operations.

Brands that invest beforehand in structured SOP fabrics gauge faster, waste less, and maintain consistent quality.

This is where Foodsure plays a critical part, helping beverage brands convert ideas into completely documented, execution-ready manufacturing systems. However, strengthening your SOP foundation is the most effective step forward if long- term growth and functional clarity matter.

Fix SOP Gaps Before They Break Your Beverage Brand

Foodsure helps beverage brands build manufacturing SOPs that eliminate inconsistency, protect quality, and enable scalable production.

Trusted by beverage founders and FMCG brands across India

Frequently Asked Questions

What is a beverage manufacturing SOP?

It is a documented system defining how a beverage is produced consistently under controlled conditions.

Why do incomplete SOPs cause manufacturing issues?

They leave room for interpretation, leading to inconsistent execution and quality variation.

Are SOP mistakes common in beverage manufacturing?

Yes, especially during early commercialisation and scale-up phases.

Do beverage startups really need SOPs early?

Yes. SOPs for beverage startups reduce dependency on individuals and enable scalable growth.

How do SOPs support beverage scale-up?

They allow pilot processes to be replicated accurately at commercial volumes.

What happens when SOPs are not followed?

Batch failures, increased wastage, and delayed production timelines occur.

Can SOPs improve shelf-life stability?

Yes. Consistent processing directly impacts product stability and shelf life.

How detailed should beverage SOP documentation be?

Detailed enough to remove assumptions and ensure repeatability across teams.

Are SOPs required for contract manufacturing?

Brand-owned SOPs are essential to maintain quality control across facilities.

When should a beverage brand formalise SOPs?

Before commercial production, not after problems appear.