Still, you aren’t just producing a drink. If you’re launching a beverage brand.

You’re constructing an operating system.

Beverage production is where numerous promising brands still struggle, not because demand is missing, but because product realities are undervalued. Authors frequently concentrate on flavour development, branding, and go-to-request strategy, assuming the product will fall into place once orders arrive.

Behind every beverage that scales successfully is a product frame designed to handle volume, variability, thickness, and compliance. Brands that fail to anticipate product challenges beforehand frequently face stalled launches, rising costs, inconsistent quality, and damaged credibility. Understanding these challenges before scaling is foundational to long-term success.

Why Beverage Production Is More Than Just Making a Drink

At an initial stage, a beverage production appears straightforward: source constituents, mix, fill, and distribute. In reality, beverage production is a tightly connected system where expression, processing, packaging, and force-chain opinions impact one another.

What works in small trials can fail under marketable conditions. Temperature variation, component gesture at scale, outfit constraints, and storehouse surroundings expose that remain retired during early development.

For new brands, libation product isn’t a backend task; it is a strategic business function.

Understanding the Beverage Manufacturing Process from Concept to Commercial Scale

Why the Beverage Manufacturing Process Breaks at Scale

One of the most undervalued challenges in libation production is navigating the beverage manufacturing process from lab expression to full-scale product.

As volume increases, brands encounter:

- Component commerce changes

- Mixing and dissolution inefficiencies

- Heat and shear perceptivity

- Shelf-life insecurity

An expression that performs well in controlled trials may behave unpredictably when reused through an artificial setup. A successful libation product aligns expressed opinions with real manufacturing conditions early ahead of request entry.

Choosing the Right Beverage Production Company

Why a Beverage Production Company Is a Strategic Partner

Numerous authors treat a beverage product company as a contract factor rather than a strategic collaborator. This approach frequently introduces avoidable pitfalls.

A capable libation product company should:

- Estimate expression scalability

- Identify processing and stability risks

- Align packaging with product gesture

- Support harmonious batch issues

Beverage products succeed when they act as system integrators, not just filling installations.

Small-Scale Beverage Production: Where Many Brands Stall

The Limits of Small-Scale Beverage Production

Small-scale beverage production is a necessary starting point, but it’s also where numerous brands turn tables. This phase reveals:

- Component sourcing challenges

- Process repetition issues

- True unit economics

Common limitations include homemade processes that can not gauge, inconsistent batch quality, and cost structures that fail at advanced volumes. Small-scale libation products should be treated as a literacy phase, not a long-term model.

Facing beverage production or scale-up challenges?

Cost Escalation Challenges in Beverage Production

Why Beverage Production Costs Rise Unexpectedly

Beyond constituents, beverage production costs come from:

- Yield loss

- Batch rejections

- Reprocessing and reformulation

- Packaging failures

Without chastened monitoring, these inefficiencies still erode perimeters. A sustainable libation production requires cost visibility across the entire manufacturing workflow.

Quality Consistency: The Fragile Core of Beverage Production

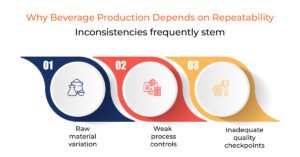

Why Beverage Production Depends on Repeatability

Consumers anticipate thickness in every bottle. Achieving this is one of the hardest challenges in libation production.

Inconsistencies frequently stem from:

- Raw material variation

- Weak process controls

- inadequate quality checkpoints

Early-stage brands constantly rely on sensitive checks alone, which are inadequate at scale. Beverage product systems must be designed for repetition, not correction.

Packaging Decisions Within Beverage Production

Why Packaging Is Part of the Production System

Packaging interacts directly with expression and processing. In a libation production, poor packaging alignment can beget:

- Product declination

- Flavour commerce

- Reduced shelf life

Packaging must be validated as part of libation production, not named purely for visual appeal.

Scaling Beverage Production Without Breaking the Brand

Why Growth Amplifies Production Weaknesses

Scaling doesn’t fix product problems; it magnifies them. Beverage product issues that feel manageable at low volumes frequently come with critical failures at scale.

Successful brands design libation production systems that anticipate growth rather than reply to it.

The Hidden Operational Load of Beverage Production

Beyond manufacturing, libation production includes:

- Attestation and traceability

- Compliance readiness

- Shelf-life monitoring

- Batch data operation

Neglecting these rudiments creates long-term vulnerability. Strong brands integrate them beforehand.

Related Blogs You May Find Useful

Explore these resources to better understand beverage production, startup planning,

cost structure, and execution before scaling your brand.

Conclusion

Many early-stage lapses aren’t demand failures but libation production failures. From navigating the libation manufacturing process to moving beyond small-scale libation products and choosing the right libation product company, early product opinions shape long-term issues. Brands that treat libation product as a structured system rather than a background task figure out hickness, control costs, and scale with confidence. This is where Foodsure’s development-led approach adds value by relating product pitfalls beforehand and aligning phrasings with real-world manufacturing conditions. The right time to stress-test your libation product strategy is before growth forces the assignment.

Fix Beverage Production Issues Before They Impact Scale

Beverage production challenges rarely resolve themselves after launch.

Get expert support on formulation, process stability, and scale readiness

to protect quality, cost, and brand credibility.

Trusted by beverage startups and FMCG brands for scalable production solutions.

Frequently Asked Questions

What is the biggest beverage production challenge for new brands?

Maintaining consistency while scaling cost-effectively.

Why does the beverage manufacturing process change at scale?

Larger volumes introduce heat, mixing, and processing dynamics not present in small batches.

Is small-scale beverage production enough to validate a product?

It validates demand, not long-term scalability.

How should brands choose a beverage production company?

By evaluating technical capability, process discipline, and scale readiness.

Can beverage production issues harm brand credibility?

Yes. Inconsistent quality and supply failures directly impact trust.

Is packaging part of beverage production planning?

Yes. Packaging affects stability, shelf life, and efficiency.

Why do beverage production costs increase unexpectedly?

Hidden inefficiencies and rework accumulate as volume grows.

When should a scale be planned in beverage production?

During the formulation and pilot production stages.

Can production challenges be fixed after launch?

They can, but corrections are more expensive post-launch.

Is beverage production only a manufacturing concern?

No. It is a strategic function affecting cost, quality, and scalability.