The chocolate market in India has changed a lot. It is no longer enough for products to be merely sweet to satisfy today’s consumers. Chocolates, for instance, must have a satin texture on the palate, bring out the cocoa flavour well, boast of natural ingredients, and maintain the same high standard each time. This is where chocolate recipe formulation can really differentiate the product.

This blog explains what really makes a chocolate recipe in India the best chocolate recipe and how professional chocolate formulation can turn an idea into a market-ready product.

Wanna Launch your Own Chocolate Brand?

What Is Chocolate Recipe Formulation?

Chocolate recipe formulation is the technical process of creating a chocolate recipe that will consistently deliver the desired taste, texture, shelf life, and cost efficiency. It is a combination of food science, ingredient functionality, and manufacturing feasibility.

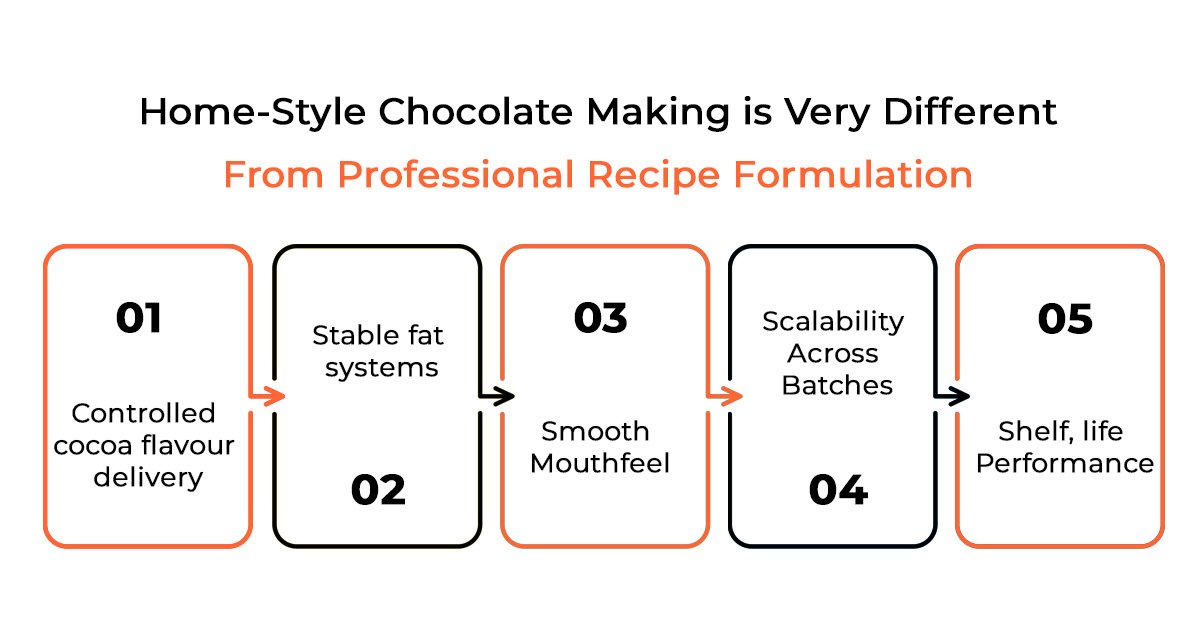

Home-style chocolate making is very different from professional recipe formulation because the latter focuses on:

- Controlled cocoa flavour delivery

- Stable fat systems

- Smooth mouthfeel

- Shelf, life performance

- Scalability across batches

A perfectly formulated chocolate is a chocolate that will perform the same in the factory, during storage, and when it is consumed.

Home-Style vs Professional Chocolate Formulation

| Aspect | Home-style chocolate | Professional Formulation |

|---|---|---|

| Goal | Taste once | Taste + consistency |

| Ingredient control | Approximate | Precisely measured |

| Texture stability | Low | High |

| Shelf life | Short | Commercially validated |

| Scale up | Not feasible | Manufacturing ready |

Why Many Chocolate Recipes Fail in the Indian Market

Many brands come out with chocolates that, at first, taste good, but then, soon after a few months, they fail.

Some of the common formulation issues are:

- Overly sweet profiles that hide the cocoa flavours

- Gross texture, either grainy or waxy

- Fat bloom in storage

- Low heat stability in the Indian climate

- Different flavours from one batch to another

These issues usually arise when the creation of the food product is treated simply as an extempore activity without prior careful consideration. An excellent chocolate recipe should be capable of anticipating these problems instead of dealing with the consequences later.

Core Ingredients for a Functional Chocolate Recipe

| Ingredient | Role in Chocolate Formulation |

|---|---|

| Cocoa Mass / Cocoa Powder | Base flavour & antioxidants |

| Cocoa Butter / Fat System | Texture, snap, melt |

| Sweetener (Sugar / Alternatives) | Taste balance |

| Functional Actives | Wellness benefit |

| Emulsifier (if required) | Texture & flow control |

Chocolate Formulation Across Different Categories

Milk Chocolate

Milk chocolates dominate the Indian market. Their success depends on:

- Proper dairy integration

- Creamy texture without heaviness

- Controlled sweetness

- Long shelf life

A strong chocolate formulation prevents flavour dullness and texture breakdown over time.

Dark Chocolate

Dark chocolate demand is growing, but formulation is complex.

Key challenges include:

- Managing bitterness

- Maintaining smooth texture at higher cocoa levels

- Preventing dryness

The best chocolate recipe formulation ensures dark chocolates remain rich and enjoyable, not intimidating.

Compound and Functional Chocolates

Protein chocolates, fortified chocolates, and compound variants require advanced food product development.

Formulation here focuses on:

- Ingredient compatibility

- Masking off-notes

- Texture stability

- Cost control

Without expert formulation, these products fail quickly in the market.

Stages of Chocolate Development

| Stage | What Happens |

|---|---|

| Concept | Functional goal defined |

| Ingredient Screening | Compatibility check |

| Bench Trials | Small batch testing |

| Sensory Testing | Taste & texture validation |

| Stability Checks | Shelf-life assessment |

| Scale-Up Trials | Machine behaviour |

| Final Recipe Lock | Commercial formulation |

Foodsure Chocolate Development Process

| Step | Foodsure Method |

|---|---|

| Ingredient Feasibility | Clean-label & stability check |

| Lab Trials | Controlled batch formulation |

| Sensory Optimization | Taste masking, if required |

| Process Design | Low-heat functional protection |

| Shelf-Life Validation | Real storage conditions |

| Scale-Up SOP | Batch-to-batch consistency |

| Manufacturing Alignment | Contract-ready process |

Clean Label and Market Expectations

Today’s consumers actively read ingredient labels. Clean-label chocolates are no longer optional.

Modern chocolate recipe formulation aligns with:

- Minimal additives

- Optimised emulsifier systems

- Natural flavour profiles

- Transparent ingredient lists

Balancing clean labels with shelf life and cost requires deep formulation expertise.

What Defines the Best Chocolate Recipe in India

The best chocolate recipe is more than just about taste. It is about consistency, stability, scalability, and consumer trust.

A good chocolate recipe formulation is a mix of flavour, texture, cost, and shelf life and also takes into consideration the Indian climate and consumer preferences. Brands that give a lot of attention to the right formulation produce products that last, not products that vanish after the launch.

If you want to make a chocolate that is different and grows sustainably, formulation is the place where it all starts.

Are you planning a chocolate launch, or are you having texture, stability, or shelf life issues?

Partner with us to transform your idea into a chocolate product that is scalable and market-ready.

Launch a Chocolate Brand with Us

Foodsure helps founders eliminate early-stage risks by aligning formulation, manufacturing, and compliance into one structured development system.

Trusted by D2C founders and FMCG brands across India

FAQ’s (Frequently Asked Questions)

What is the best functional chocolate recipe?

The best functional chocolate recipe features top-notch cocoa, pure sweeteners, friendly functional actives, and low-temperature processing confirmed by R&D.

How is chocolate formulation done commercially?

Commercial chocolate formulation involves the screening of ingredients, lab trials, sensory optimisation, stability testing, and scale-up based on SOP.

Why is a chocolate R&D lab important?

A chocolate R&D lab prevents texture failure, taste issues, fat bloom, and shelf-life instability during scale-up.

Can functional chocolate be developed without preservatives?

Yes, if moisture, fat system, and processing are controlled properly during formulation.

How long does chocolate development take?

Typically 6-12 weeks, depending on complexity, functional ingredients, and scale-up requirements.