Want to expand your range with high-quality instant premixes but avoid heavy investment in manufacturing units? Contract manufacturing of instant premixes (OEM) is the smart solution. With rising demand for ready-to-drink beverages, soups, and dessert mixes, partnering with an expert manufacturer helps you launch faster, ensure consistent quality, and scale without production hassles.

In this blog, explore how third-party manufacturing of instant premixes can simplify growth and strengthen your brand in this fast-growing market.

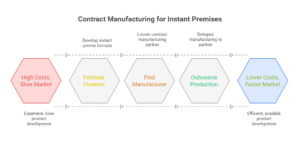

What is Contract Manufacturing of Instant Premixes?

Contract manufacturing of instant premixes (OEM) is a model where you outsource production to expert food premix manufacturers in India. You create the formula, and the manufacturer handles large-scale production, quality control, and compliance, making it a smart approach for scaling your premix business through reliable third-party food manufacturing.

➣ Fast-Growing Demand:

The Indian premix market is projected to cross USD 2,305.9 million by 2035, registering a CAGR of 14.8% over the forecast period.

➣ Why Instant Premixes Are Popular:

Consumers prefer quick and nutritious options like instant poha, dosa mixes, health drinks, and dessert premixes, covering both traditional and modern needs.

➣ Hot Segments in India:

Breakfast premixes, beverage mixes, and bakery/dessert premixes are trending across retail, D2C, airlines, hospitals, and export markets.

➣ Rising Third-Party Model:

More startups are choosing third-party food manufacturing to save investment, access R&D, and ensure FSSAI/ISO compliance.

➣ Export & Private Label Growth:

Demand from Southeast Asia, the Middle East, the USA, and the UK is increasing, especially for clean-label Indian products manufactured by trusted food premix manufacturers in India.

➣ Search Trends Up:

Searches for “instant premix manufacturer” and related terms are rising, showing strong market interest in starting or scaling a premix business.

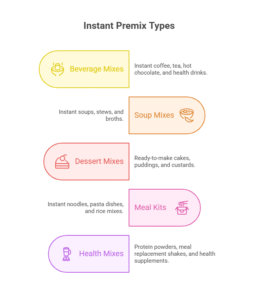

Types of Instant Mixes

The world of instant premixes is diverse, catering to various consumer needs and preferences. Contract manufacturing of instant premixes can help you with every type of instant mix. Some popular types include:

- Beverage Mixes: Instant coffee, tea, hot chocolate, and health drinks.

- Soup Mixes: Instant soups, stews, and broths.

- Dessert Mixes: Ready-to-make cakes, puddings, and custards.

- Meal Kits: Instant noodles, pasta dishes, and rice mixes.

- Health and Nutritional Mixes: Protein powders, meal replacement shakes, and health supplements.

Models of Third-Party Manufacturing for Instant Premixes

| Model | What You Get | Best For |

|---|---|---|

| White Label | Pre-formulated instant premixes (like poha, idli, and tea premix) ready for your brand packaging | Startups, D2C brands, or retailers wanting a fast market entry with low R&D investment |

| Private Label | Standard instant premix recipes with flexibility to tweak flavours, ingredients, packaging & design | Brands looking for mild customisation while keeping contract manufacturing cost-effective |

| OEM / Contract | Fully custom instant premix development—recipe, texture, packaging, certifications (FSSAI, ISO) | Established food brands, nutrition startups, or exporters wanting unique, proprietary blends |

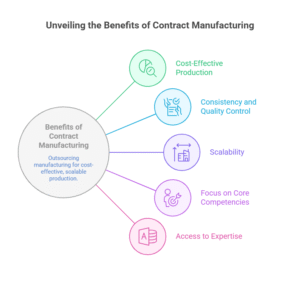

Benefits of Contract Manufacturing for Instant Premixes

1. Cost-Effective Production: With third-party food manufacturing, you avoid heavy factory setup costs and can reinvest savings into marketing and R&D to grow your premix business.

2. Consistency & Quality Control: Experienced food premix manufacturers in India follow strict quality standards to ensure uniform taste, texture, and safety in every batch.

3. Scalability: Contract manufacturing allows you to scale production up or down based on demand without investing in machinery or infrastructure.

4. Focus on Core Strengths: Outsourcing production lets you concentrate on branding, innovation, and sales while experts manage operations.

5. Access to Expertise: Established food premix manufacturers in India bring technical know-how, process efficiency, and formulation expertise to strengthen your premix business.

How to Start the Contract Manufacturing Process

Starting a contract manufacturing of instant premixes partnership involves several key steps:

- Initial Inquiry and Requirement Gathering

- Preliminary Discussion and Feasibility Analysis

- Proposal and Quotation

- Product Development and Sample Approval

- Contract Agreement

- Production and Quality Assurance

- Packaging and Delivery

- Ongoing Relationship Management

- Scaling and Expansion

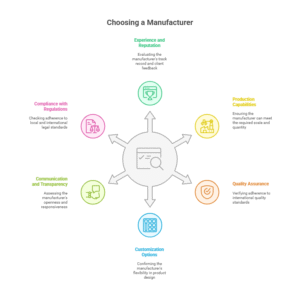

Factors for Choosing the Right Contract Manufacturer for Instant Premixes

Selecting the right contract manufacturer is crucial to the success of your product. Here are some key factors to consider:

➣ Experience and Reputation: It will be relevant to see manufacturers with adequate experience in the production of an instant premix. Look for compulsory elements of all business websites, such as contact information, client reviews and testimonials, and success stories.

➣ Production Capabilities: Make sure that the manufacturer is capable of creating your product in the quantity and scale that you want.

➣ Quality Assurance: The manufacturer must, therefore, have a sound quality assurance program and standards to propagate and must be accredited with international standards like ISO 22000, FSSC 22000, and BRC, among others.

➣ Customisation Options: Any good contract manufacturer should allow the formulation and packaging of the product to suit your needs as a client.

➣ Communication and Transparency: Taking time to discuss issues or share information is very important in any partnership. There is a need to engage the manufacturer in a manner that the manufacturer discloses all it takes to make the item and deliver it as and when agreed on.

➣ Compliance with Local Regulations: Verify that the manufacturer is particular with FSSAI requirements, US FDA, NPOP, NOP USDA, Legal Metrology, and all other legal bindings applicable in your country.

Why Choose Foodsure as Your Contract Manufacturer for Instant Premixes?

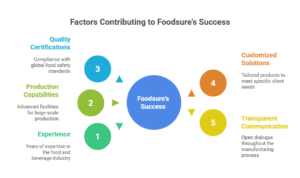

Foodsure stands out as a leading contract manufacturer for instant premixes, offering:

- Experience: With years of experience in the food and beverage industry, Foodsure has the expertise to deliver high-quality instant premixes that meet high standards.

- High Production Capabilities: Our latest technological facilities are equipped to handle large-scale production while maintaining the highest levels of quality.

- Commitment to Quality: We are certified with FSSAI, US FDA, ISO 22000, FSSC 22000, and BRC, ensuring compliance with global standards.

- Perfect Solutions: At Foodsure, we offer amazing solutions to meet your specific product requirements, from formulation to packaging.

- Transparent Communication: We maintain clear and open communication throughout the manufacturing process, ensuring a smooth and successful partnership.

Launch Your Brand Today With Foodsure

Contract manufacturing of instant premixes or OEM for instant premixes is an efficient way for businesses to expand their product offerings without significant capital investment. By choosing the right contract manufacturer, companies can ensure consistent quality, cost-effective production, and the ability to scale up operations.

Foodsure, with its expertise, advanced facilities, and commitment to quality, is your ideal partner for contract manufacturing services.

Contact us at +91 8130404757 today!

FAQs

1. What is the minimum order quantity (MOQ)?

MOQ depends on the product and packaging, but flexible batch sizes are usually available.

2. How much does it cost to start?

Costs vary by ingredients and volume, but third-party food manufacturing avoids heavy factory investment.

3. What certifications are required?

FSSAI is mandatory; ISO, FSSC, BRC, and US FDA are added advantages for exports.

4. How long does it take to launch?

After sample approval, launch timelines are usually much faster than setting up your own unit.

5. Is there export potential for instant premixes?

Yes, Indian premixes are in high demand globally, especially clean-label and health-focused products.