Looking for ways to offer tasty pasta in your product range without investing in new production lines? All this thinking is kind of giving you a slightly triggering feel. You’re right, and here’s an opportunity for you: contract manufacturing of pasta is your solution. You don’t have to invest in expensive equipment and machinery when you are a new manufacturer of pasta, because you can partner with a capable contract manufacturer of pasta today to bring your products into the market within a shorter time and at a lower cost.

Now, let’s look into this blog and understand how this smart approach to contract manufacturing of pasta can be used to increase your pasta range and meet your clients’ needs!

What is the Concept of Contract Manufacturing of Pasta?

Contract manufacturing of pasta, or OEM, means outsourcing pasta manufacturing to expert pasta manufacturers in India instead of setting up your own factory. You share your recipe and specifications, and the pasta manufacturer handles production, quality, and packaging. Many spaghetti manufacturers in India offer customised solutions, helping you reduce costs and focus on branding and sales.

Why Choose a Contract Manufacturer of Pasta: Quick Market Insights

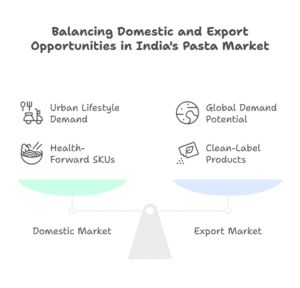

1. Booming Market: The Indian pasta market size reached USD 1.06 billion in 2024. Looking forward, the publisher expects the market to reach USD 3.80 billion by 2033, exhibiting a growth rate (CAGR) of 14.47% during 2025-2033.

2. Rising Demand for Healthy Variants: Whole wheat, quinoa, gluten-free, and high-protein options are driving brands to collaborate with pasta manufacturers in India and spaghetti manufacturers in India for customised SKUs.

3. Export Potential: Every growing pasta manufacturer is exploring exports to Africa, Southeast Asia, and the Middle East, with rising demand for private-label and clean-label products.

4. Trending Searches: Searches like “contract manufacturing pasta in India” and “bulk pasta supplier” show strong demand for outsourced production and faster market entry.

Partnering with a contract manufacturer in the food sector gives you faster market entry, flexible SKUs, and zero production setup hassle.

Types of Pasta You Can Opt For in Your Business

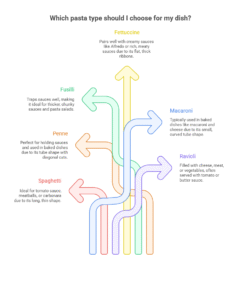

The world of pasta is diverse, catering to various consumer needs and preferences. Some popular types include:

- Spaghetti: Long, thin, cylindrical pasta commonly served with tomato sauce, meatballs, or carbonara.

- Penne: Short, tube-shaped pasta with diagonal cuts at the ends, perfect for holding sauces and used in baked dishes.

- Fusilli: Spiral-shaped pasta that traps sauces well, making it ideal for thicker, chunky sauces and pasta salads.

- Fettuccine: Flat, thick ribbons of pasta that pair well with creamy sauces like Alfredo or rich, meaty sauces.

- Macaroni: Small, curved tube-shaped pasta typically used in baked dishes like macaroni and cheese.

- Ravioli: Square or circular pasta filled with cheese, meat, or vegetables, often served with tomato or butter sauce.

Types of Third-Party Manufacturing Models for Pasta

| Model | What You Get | Best For |

|---|---|---|

| White Label | Pre-made pasta (e.g., penne, fusilli) in regular variants, ready for branding | New pasta brands or D2C startups wanting quick market entry |

| Private Label | Standard pasta recipes with customizable flavours, shapes, and packaging | Food businesses seeking differentiation without major R&D cost |

| OEM / Contract | Fully customised pasta formulation, ingredients, size, and branded packaging | Established companies with unique product ideas or nutritional positioning |

Process of Contract Manufacturing for Pasta

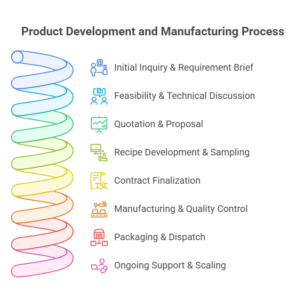

Launching your pasta brand through contract manufacturing involves these essential steps:

- Initial Inquiry & Requirement Brief

- Feasibility & Technical Discussion

- Quotation & Proposal

- Recipe Development & Sampling

- Contract Finalisation

- Manufacturing & Quality Control

- Packaging & Dispatch

- Ongoing Support & Scaling

Benefits of Contract Manufacturing for Pasta

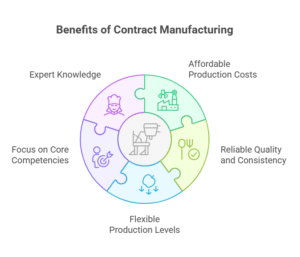

1. Affordable Production Costs: With contract manufacturing of pasta, you avoid heavy investment in factory setup and operations. Leading pasta manufacturers in India handle large-scale pasta manufacturing, allowing you to invest more in branding and R&D.

2. Reliable Quality & Consistency: An experienced pasta manufacturer ensures uniform taste, texture, and quality in every batch, building long-term customer trust.

3. Flexible Production Levels: Partnering with spaghetti manufacturers in India offers scalable production, so you can increase or reduce volumes based on market demand without infrastructure costs.

4. Focus on Core Business: Outsourcing production lets you focus on innovation, new product development, and marketing while experts manage operations.

5. Expert Knowledge: Established pasta manufacturers in India bring technical expertise and process efficiency to optimise quality and output.

Cost Structure for Contract Manufacturing of Pasta in India

| Cost Component | Details |

|---|---|

| Minimum Order Quantity (MOQ) | Starts from 1,000 kg to 3,000 kg per batch, depending on pasta shape, flour type, and packaging needs. |

| Per-Kilo Manufacturing Cost | ₹55 – ₹120 per kg based on ingredients (semolina, multigrain, millet), drying method, and quality grade. |

| Recipe Development (Optional) | ₹1 Lakh – ₹2 Lakh for custom formulations like gluten-free, high-protein, or millet-based pasta. |

| Packaging Design & Branding | ₹25,000 – ₹75,000 for custom packaging design, labels, and print-ready files. |

| Regulatory & Lab Testing | ₹20,000 – ₹60,000 including FSSAI compliance, shelf-life testing, and nutrition facts. |

| Working Capital Needs | Advance purchase of raw materials; typically, 1-2 months of rolling stock is recommended. |

Factors for Choosing the Right Contract Manufacturer for Pasta

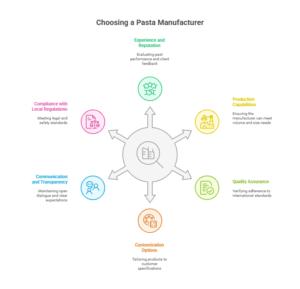

Selecting the right contract manufacturer is crucial to the success of your product. Here are some key factors to consider:

1. Experience & Reputation: Choose established pasta manufacturers in India or reliable spaghetti manufacturers in India with proven expertise in pasta manufacturing, verified reviews, and strong client portfolios.

2. Production Capabilities: Ensure the pasta manufacturer can meet your required volumes, formats, and scalability needs.

3. Quality Assurance: Look for certifications like ISO 22000, FSSC 22000, and BRC to ensure safe and consistent contract manufacturing of pasta.

4. Customisation Options: A good partner should offer flexible formulation and packaging solutions tailored to your brand.

5. Communication & Transparency: Clear timelines, open communication, and defined processes are essential for smooth collaboration.

6. Regulatory Compliance: Confirm compliance with FSSAI, US FDA, NPOP, NOP USDA, Legal Metrology, and other applicable regulations.

Why Choose Foodsure as Your Contract Manufacturer?

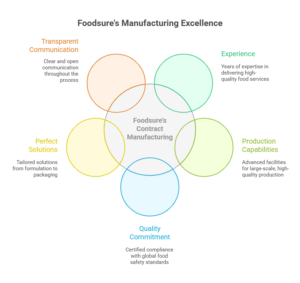

Foodsure stands out as a leading contract manufacturer for pasta, offering:

- Experience: With years of experience in the food and beverage industry, Foodsure has the expertise to deliver high-quality pasta services that meet high standards.

- High Production Capabilities: Our latest technological facilities are equipped to handle large-scale production while maintaining the highest levels of quality.

- Commitment to Quality: We are certified with FSSAI, US FDA, ISO 22000, FSSC 22000, and BRC, ensuring compliance with global standards.

- Perfect Solutions: At Foodsure, we offer amazing solutions to meet your specific product requirements, from formulation to packaging.

- Transparent Communication: We maintain clear and open communication throughout the manufacturing process, ensuring a smooth and successful partnership.

Launch Your Pasta Brand with Expert Contract Manufacturing at Foodsure!

Contract manufacturing or OEM of pasta is a smart way for businesses to expand their product offerings without significant capital investment. By choosing the right contract manufacturer, companies can ensure consistent quality, cost-effective production, and the ability to scale up operations. Foodsure, with our highly specialised equipment and extensive expertise, is ready to assist you in getting your non-dairy whipped cream to market.

Call us at +91 8130404757 to know how we can help your brand. Book Your Free Consultation Now.

FAQs

1. What is the minimum order quantity (MOQ)?

Typically 1,000-3,000 kg per batch, depending on product type and packaging.

2. Can I create customised or healthy pasta variants?

Yes. Leading spaghetti manufacturers in India offer whole wheat, millet, gluten-free, and high-protein options.

3. What is the cost of pasta manufacturing in India?

Usually ₹55-₹120 per kg, based on ingredients, volume, and packaging.

4. How long does it take to launch?

After recipe and packaging approval, launch timelines are much faster than setting up your own factory.

5. What certifications should a pasta manufacturer have?

FSSAI compliance is essential; ISO 22000, FSSC 22000, BRC, and US FDA are added advantages.