Drink Product Development is no longer a creative trial confined to a laboratory bench. It’s a structured, science-driven discipline where food chemistry, nutrition science, recycling technology, and consumer behaviour intersect. Today’s beverage market demands more than good taste; it expects functional value, consistency at scale, non-supervisory preparedness, and marketable viability.

Whether the aim is hydration, energy, heartiness, or life positioning. Drink Product Development determines whether a libation remains an idea or becomes a sustainable product. Brands that succeed in understanding that expression, processing, and confirmation are as critical as branding and marketing. This scientific foundation is what separates short-lived launches from beverages that earn repeat consumption and long-term trust.

This composition breaks down the wisdom of drink product development, explaining how ideas move from conception to shelf through disciplined functional drink development, drink formulation services, and beverage concept development without relying on terrain-specific hypotheticals or trends.

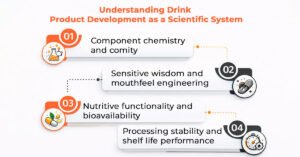

Understanding Drink Product Development as a Scientific System

At its core, drink product development is a system, not a single step.

It combines:

- Component chemistry and comity

- Sensitive wisdom and mouthfeel engineering

- Nutritive functionality and bioavailability

- Processing stability and shelf-life performance

Each variable influences the others. Changing a sweetener alters density, which affects flavour release, which also impacts consumer perception. Scientific drink product development anticipates these relations beforehand rather than correcting them at the manufacturing stage.

Successful drink brands design backwards from real-world consumption, not forward from lab success. This mindset ensures that Drink Product Development remains practical, scalable, and commercially aligned.

Functional Drink Development: Designing Beverages with Purpose

Why Functional Drink Development Requires Precision

The development of functional drinks targets the provision of a particular benefit, hydration or energy balance, gut comfort or nutritional supplementation. In contrast to traditional drinks, the functionality has to be useful during the shelf life and at the time of digestion.

This must be with great consideration of:

- Dosage accuracy

- Ingredient stability in Liquid systems

- Reaction with active and base liquid

The failure in the development of functional drinks occurs when the trends are followed without a thorough study of the formulation science. The efficacy is not guaranteed just by the presence of a given ingredient. That ingredient lies in the behaviour of the beverage matrix science.

Balancing Function and Sensory Acceptance

A healthy drink would still need to be a tasty one. Development groups use sensory science to balance the bitterness, acidity, sweetness, and texture and maintain functionality. It is this balance that regulates repeat purchase, and not labelling claims in isolation.

The success of functional drink development is realised when both the delivery of the benefits and the principles of enjoyment are supported by science.

Beverage Formulation Services: Where Science Becomes Structure

The Role of Beverage Formulation Services

Beverage formulation services are the ones that translate abstract concepts into normal, measurable, and testable liquids. This is the stage of beverage product development that involves:

- Use of incompatible ingredients

- Establishing the best concentrations

- Determining pH, viscosity and flavour stability

Brands will not be consistent, separated or have off notes during storage and transportation without professional beverage formulation services. In services, brands risk inconsistency, separation, or off notes during storage and transport.

Stability, Shelf Life, and Process Compatibility

A beverage will perform well in small-scale trials but will not be able to stand commercial processing environments. The services of the beverage forming evaluate the response of the formulations to heat treatment, homogenization, carbonation, and packaging.

This scientific evaluation makes the Drink Product Development consistent with the actual manufacturing conditions and not the idealistic laboratory conditions.

Beverage Concept Development: From Idea to Feasible Product

Turning Concepts into Viable Beverages

The creativity and feasibility are bridged by the development of beverage concepts. Most of the ideas of beverages do not stop due to a lack of appeal; they just fail due to technical limitations or cost ineffectiveness.

In the beverage concept development process, teams evaluate:

- Feasibility of sourcing ingredients

- Cost implications at scale

- Limits and risks of processes

The stage of development of drink products narrows the enthusiasm for ambition through the prism of scientific research, and enables the ideas to resist reality in terms of production.

Aligning Concept with Consumer Behaviour

Interaction with drinks by consumers is also considered during scientific beverage concept development in the form of frequency, portion size and context of use. Such insights drive the strength of formulation, a type of package, and shelf-life specifications.

Creativity founded on data enables drink product development to reduce the expensive pivots during the later stage of the lifecycle.

Ingredient Science in Drink Product Development

The Chemistry Behind Liquid Systems

Liquids are complex systems. Depending on formulation conditions, ingredients dissolve, suspend, interact or degrade. The solubility, emulsification and stabilisation methods require a thorough level of knowledge in the development of beverage products.

Incorrect ingredient science brings about:

- Sedimentation

- Flavor fade

- Texture inconsistency

Scientific formulation is a matter that predicts these challenges and does not respond to them after the launch.

Sweeteners, Acids, and Flavour Systems

Acid and sweetness affect who perceives it. Their combination in the beverage product development field is a scientifically controlled calibration of the components to control the release of flavours and oral sensation without functional ingredients.

Accuracy here would ensure that each production lot is consistent and there is an increase in product shelf life.

Processing Science and Its Impact on Drink Product Development

Why Processing Matters

Processing is a non-neutral process. The beverage chemistry is strongly affected by thermal energy, pressure and mechanical forces. During beverage formulation, the parameter of processing is considered at the initial stages of developing the drink products to avoid the loss of nutrients, alteration of taste profile and deterioration of properties of the drink products. Proper knowledge of this science helps the brands to create beverages that will be honest in the whole production and consumption chain.

Scale-Up as a Scientific Challenge

Scaling is also often the most significant point of failure in the manufacturing of beverages. What works satisfactorily at 10 litres might act in a surprisingly significantly different manner as produced at 10,000 litres. Formulations are tested on simulated business conditions to determine predictable results in terms of product development of scientific drinks.

Quality, Compliance, and Validation in Drink Product Development

Building Consistency and Trust

Consistency is a scientific achievement. Drink Product Development relies on validation protocols to ensure every batch meets defined specifications.

This includes:

- Sensory benchmarks

- Physical and chemical parameters

- Shelf-life confirmation

Without this discipline, brands threaten quality drift over time.

Compliance as Part of the Development Process

Rather than treating compliance as a final chain, scientific Drink Product Development integrates it into expression and processing opinions. This reduces reformulation threat and supports smoother commercialisation.

Recommended Blog – How to Launch a Beverage Product

Why Science-First Drink Product Development Wins Long Term

Science-driven Drink Product Development creates drinks that are:

- Stable

- Scalable

- Secure

It reduces recalls, reformulations, and market confusion. Brands established on scientific rigour adapt better to market shifts because their foundations are flexible.

When expression, function, and feasibility align, drinks earn credibility with consumers, mates, and controllers likewise.

Conclusion

The wisdom of Drink Product Development defines whether a libation remains an idea or becomes a dependable request pantomime. From functional drink development to libation expression services and structured libation conception development, every stage demands perfection, confirmation, and foresight.

Brands that invest in scientific development beforehand avoid expensive corrections later. This chastened approach not only improves product quality but also accelerates request readiness and long-term scalability.

For brigades seeking to make potables that balance invention with trustworthiness, working with mates who understand Drink Product Development at a molecular and marketable level makes a measurable difference. Foodsure supports this trip by aligning wisdom, strategy, and prosecution, helping libation ideas evolve into products that are ready for real-world success.

Frequently Asked Questions

What is Drink Product Development?

Drink Product Development is the scientific and strategic process of creating beverages that are stable, scalable, and market-ready.

Why is functional drink development complex?

Because functional ingredients must remain effective, stable, and palatable throughout shelf life and consumption.

What do beverage formulation services include?

They cover ingredient selection, formulation optimisation, stability testing, and processing compatibility.

How is beverage concept development different from formulation?

Beverage concept development evaluates feasibility, cost, and positioning before detailed formulation begins.

How many times should Drink Product Development be tested?

Multiple iterations are standard to validate stability, taste, and processing behaviour.

Why do beverages fail during scale-up?

Because processing conditions change ingredient behaviour, which is often overlooked in early development.

Can Drink Product Development reduce launch risks?

Yes, scientific validation minimises reformulation, recalls, and quality inconsistencies.

Is compliance part of Drink Product Development?

Yes, integrating compliance early prevents delays and redesigns later.

How long does Drink Product Development usually take?

Timelines vary depending on complexity, functionality, and validation requirements.

Who should manage Drink Product Development?

Experienced formulation and development teams with both scientific and commercial understanding.