The majority of food company founders are characterised by an initial phase of enthusiastic vision and a severely underestimated budget.

“I have an excellent recipe. All that’s needed is the production cost.”

This singular belief has, perhaps, silently and gradually, drained the banks of startups in the food industry more than any other notion. Because the reality is that in India, the product development cycle for the food category is not an easy one; it involves a lot of investments through stages comprising science, testing, compliance, iteration, and scale-readiness. And if you do not know the actual food product development cost and how can you develop a food product in India, right from the start, the entire process will eventually teach you, but at a cost.

Want to optimise your Food Business? Request a free consultation!

Explore Our Exclusive Food Product Development

Our collaboration with new brands and food companies has revealed that most products do not go off the market because they taste bad; rather, the reason is that the cost of development was misunderstood, underestimated, or planned too late.

Through this blog, we are going to illustrate the real cost of developing a food product in India, the sources of the cost, and the significance of properly budgeting as being on par with the perfecting of the taste.

Breaking Down Food Product Development Expenses

The food product development is a continuous process rather than a one-time event. It is not limited to just coming up with a delectable recipe. An actual estimate of the expenses related to food production development in India consists of R&D, trials with different ingredients, food formulation, decisions regarding packaging, validation of shelf-life, licensing, and preparation for manufacturing.

Every phase contributes to the product’s value, but it also increases the price. If these stages are hurried or neglected, the product may suffer later in the form of rework, delays, or failure to be produced on a large scale.

Picture development as erecting a sturdy foundation. You might not see the foundation once the product is displayed for sale, but everything is built on it.

How Much to Budget for Developing a Food Product in India?

The costs are not uniform and depend on the category and complexity, but the following is a fairly practical food and beverage development start-up point in India:

- General food formulation: ₹1,50,000 – ₹2,50,000

- Functional or fortified products: ₹3,00,000 – ₹5,00,000

- Innovative or claim-heavy products: ₹7,00,000 – ₹10,00,000+

The sums that were mentioned above take into account just the formulation and the initial Research & Development stages.

When entrepreneurs are inquiring about food product development costs in India, we always emphasise that formulation is just one part of the process, not the whole picture.

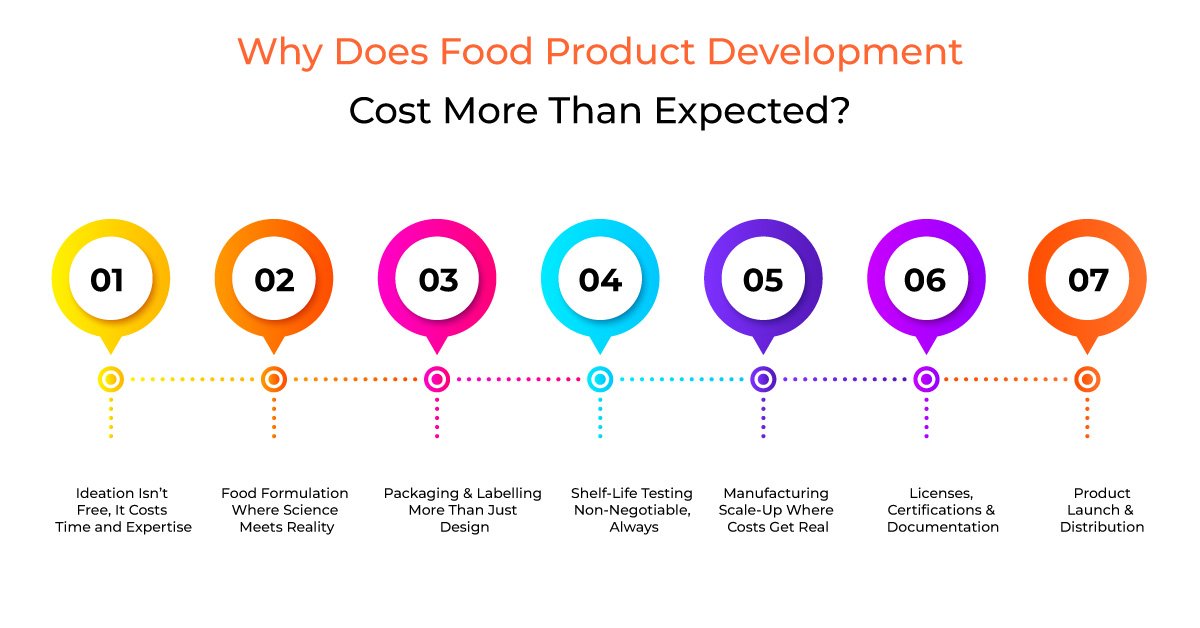

Why Does Food Product Development Cost More Than Expected?

1. Ideation Isn’t Free, It Costs Time and Expertise

The idea phase does not seem to cost much because it is free of charges. Nevertheless, it still entails the same activities as market research, competitor analysis, policy checking, and trend studies. Internally or dialoguing with an expert, surely, time and knowledge are involved.

The cost for getting strategic feasibility and initial guidance very often lies between ₹50,000 and ₹2,00,000. This initial understanding usually keeps millions at bay later.

2. Food Formulation: Where Science Meets Reality

Most of the budgets are starting to stretch in this area. Food formulation is not just about combining ingredients; it is about their solidarity under actual conditions.

- Testing of the ingredients’ functions

- Multiple tests were done in the lab

- Sensory evaluation (flavour, texture, and mouthfeel)

- Nutritional and safety alignment

Typically, three to five rounds of trials are required for most products. Depending on the complexity of the product, this stage alone has the potential to cover a wide range of food product development costs in India.

3. Packaging & Labelling: More Than Just Design

Packaging, undeniably, is a key element in the preservation of a product, its safety, and adherence to regulations. Besides being attractive, it has to safeguard the item and fulfil the legal obligations.

- Choosing the right kind of packaging material

- Organic and inorganic stability testing and compatibility

- Regulatory labelling and validation

- Barcode and compliance checks

The overall packaging-related development cost can range from ₹50,000 to ₹3,00,00,0 depending upon the extent of assistance needed.

4. Shelf-Life Testing: Non-Negotiable, Always

Shelf-life testing is one of the costs that are least recognised but most significant. Nevertheless, it is indispensable to both retail and consumer acceptance.

- Microbiology testing

- Accelerated and real-time studies

- Simulations of storage conditions

Skipping this step is impossible. It can range from ₹40,000 to ₹1,50,000 added to your overall food product development cost in India, depending on the type of product.

5. Manufacturing Scale-Up: Where Costs Get Real

It is a common belief that a laboratory-tested recipe will yield the same results when implemented in a factory. However, the real situation is the opposite, as production size requires different tests of pilot runs, compatibility of equipment, and even a change of formulations.

- Pilot batch trials

- Tests for sourcing bulk ingredients

- Process optimization

This is the phase where food product development takes a step closer to reality and where bad planning can rapidly increase costs.

6. Licenses, Certifications & Documentation

Regulatory compliance is one more invisible yet very important cost. In India, it is obligatory to get FSSAI licensing, and, additionally, some certifications may be needed based on your product category and market area.

- FSSAI registration

- Nutritional and allergen analysis

- Claim validation documentation

This can increase your development cost by anywhere between ₹25,000 to ₹1,50,000+.

7. Product Launch & Distribution

The development process does not finish once the product is prepared. Marketing, sampling, platform onboarding, and distribution setup are some of the important steps in launching.

The budgets allocated for launches are quite different and can range anywhere from ₹1,00,000 for minor D2C launches to ₹10,00,000 or even more for large-scale rollouts. Though this is not a part of formulation, it still accounts for a significant portion of the real food product development cost in India.

Overlooked Expenses in Food Product Development No One Mentions

- Iteration costs: Hardly a product is successful in its first proposed version

- Minimum order quantities: Also, the materials and containers might require buying in large quantities

- Re-testing: Modifying the composition to regain the previous quality will definitely necessitate new testing

- Time delays: Delays mean more money spent, less power, and a lost chance in the market

All these hidden layers frequently make the development cost more than the founders anticipated.

What Influences Cost Variation Between Products?

- Functional or speciality ingredients

- Health or nutrition claims

- Export readiness

- Complex processing methods

- Longer shelf-life requirements

The more intricate the claims are, the more the investment in food product development to support the claims will be.

Why Investing in Prototyping Pays Off Big Time

Prototyping is a process that gives you the opportunity to test the product idea before you completely dedicate yourself to it. It is a way of analysing the whole process and taking little steps in the right direction – it discovers defects at an early stage, checks the market and thus saves the overall production costs and so on.

Certainly, prototyping will cause an increase in R&D costs; nevertheless, it will stop mistakes that will be much more expensive to correct later on. Based on our experience, it is one of the most efficient ways to manage food product development costs in India.

India vs World-wide Development Costs

India continues to be a place of food innovation where cost is not a big factor. A product that will need an investment of ₹2 – 4 lakh in India will have a price of $15,000 or even more in the US or Europe.

Nevertheless, the costs are different even in India according to the city, lab facilities, where to buy the ingredients, and the infrastructure for manufacturing. Level of importance is given to the place, but more to planning.

Conclusion

A product in the market does not mean the death of an expensive development food product. If the expenditure was not a part of a properly planned investment, the product would be dead.

Knowing the real food product development cost in India will give you a clear view of your budget and allow you to make the right decisions while at the same time avoiding nasty surprises. It is a fact that with the proper research and development setup and a very careful approach to formulation, development turns into an investment that reaps rewards or a place to throw your money away.

If you are developing a product that will last after the launch, then planning the costs should be given the same level of attention as taste and branding. The smartest brands do not just inquire about the price tag; they go further to ask how they can make the best of it.

Launch Your Food Product with Zero Compliance Hassles – Get Expert Help Today!

(4.9 Rating)

Frequently Asked Questions

The average food product development cost in India?

In India, food product development costs usually lie between ₹1.5 lakhs and ₹10-15 lakhs, depending on the product complexity and claims made on the product.

Why is food product development more expensive than expected?

This is because it entails not merely the recipe but also Research and Development, food formulation, lab trials, shelf-life testing, packaging, licenses, and scale-up.

What elements vicariate the food product development cost in India?

More money needs to be spent on the development costs with the inclusion of functional ingredients, special health claims, longer shelf life, export requirements, and multiple formulation trials.

Does food formulation have the highest costs in product development?

Yes, Food formulation takes the biggest share as multiple lab trials, ingredient testing, and compliance validation are mandatory requirements.

Can there be reductions in food product development costs?

The costs actually can be minimised with appropriate planning, early checking on feasibility, and a well-strategised Research & Development. Now, skipping one or more steps leads to an increment in cost.

Should I conduct shelf-life testing for my food product?

Certainly. Shelf-life testing is a prerequisite for food safety, regulatory compliance, and retail acceptance.

How many formulation trials are needed typically in food processing?

A majority of the products need three to five trials for formulation in order to get the desired flavour, texture, shelf life of the product, and compliance with the laws.

Is the cost of food product development containing the licenses?

In addition to licensing and certifications like FSSAI, there are extra costs that depend on the product type and market, and they vary.

What makes scale-up a reason for the increase in the development cost?

Scaling up involves pilot production, technology compatibility testing, and reformulation, which in turn lead to increased development costs in a painstaking process.

Is it costlier to make a food product in India than abroad?

Yes, producing a food product in India is not only much cheaper than in the US or Europe but also of the same quality standards.