Roasted makhana (fox nuts) used to be a fasting food, but now it has become a fast-growing, healthy snacking category. It is currently seen as a clean, label, light, and functional snack in modern trade, e-commerce, and private-label portfolios.

Talk to our food formulation experts →

However, an amazing roasted makhana snack is not the result of simply roasting in a casual way or kitchen experiments. A systematic roasted makhana recipe formulation process is a must for the very flavour, crunch stability, shelf life, and commercial scalability of the product.

This blog discusses how a roasted makhana snack recipe is formulated by a transparent, step-wise commercial process that can be used by startups, private labels, and scaling FMCG brands.

What Makes a Good Roasted Makhana Snack Recipe?

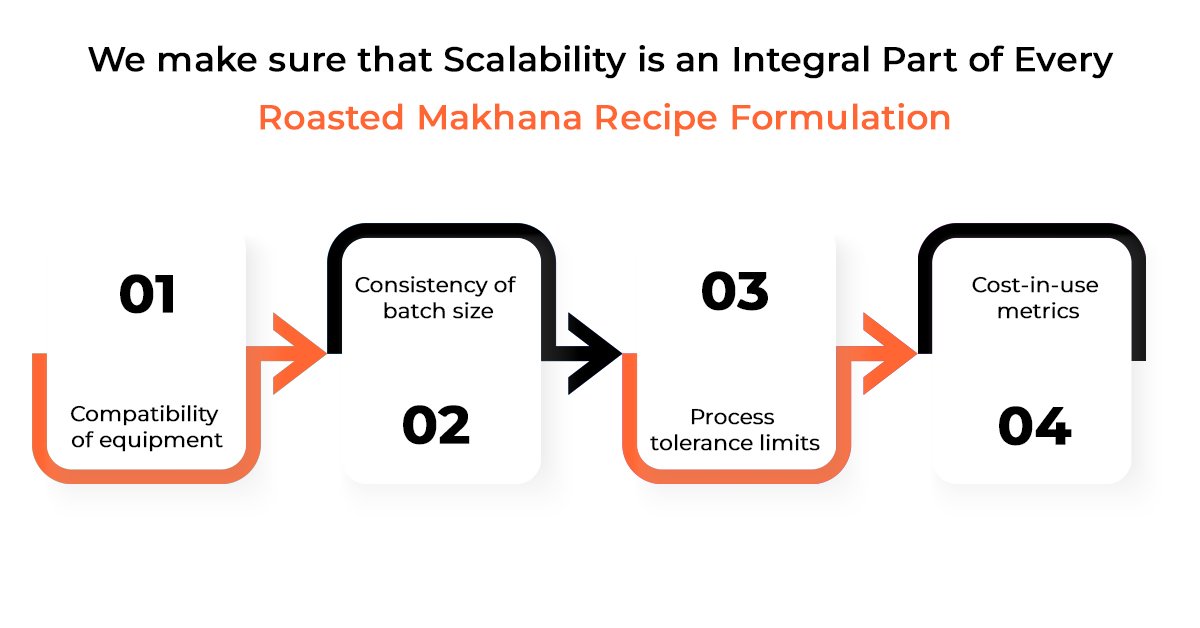

A great roasted makhana recipe is more than just flavour. It is about how consistently the product can perform across batches, different machines, storage, and distribution when a consumer buys the product at different times and locations.

The factors determining the commercial success of a roasted makhana snack recipe are:

- Moisture control

- Oil absorption management

- Spice and seasoning adhesion

- Crunch retention over time

- Shelf-life stability

This is the point where commercial roasted makhana recipe formulation differs from home-style roasting. Home recipes are all about immediate taste, whereas commercial recipes are geared towards repeat purchase and predictable performance.

Talk to our food formulation experts →

Stage-Wise Roasted Makhana Snack Recipe Formulation Process

Stage 1: Raw Makhana Selection

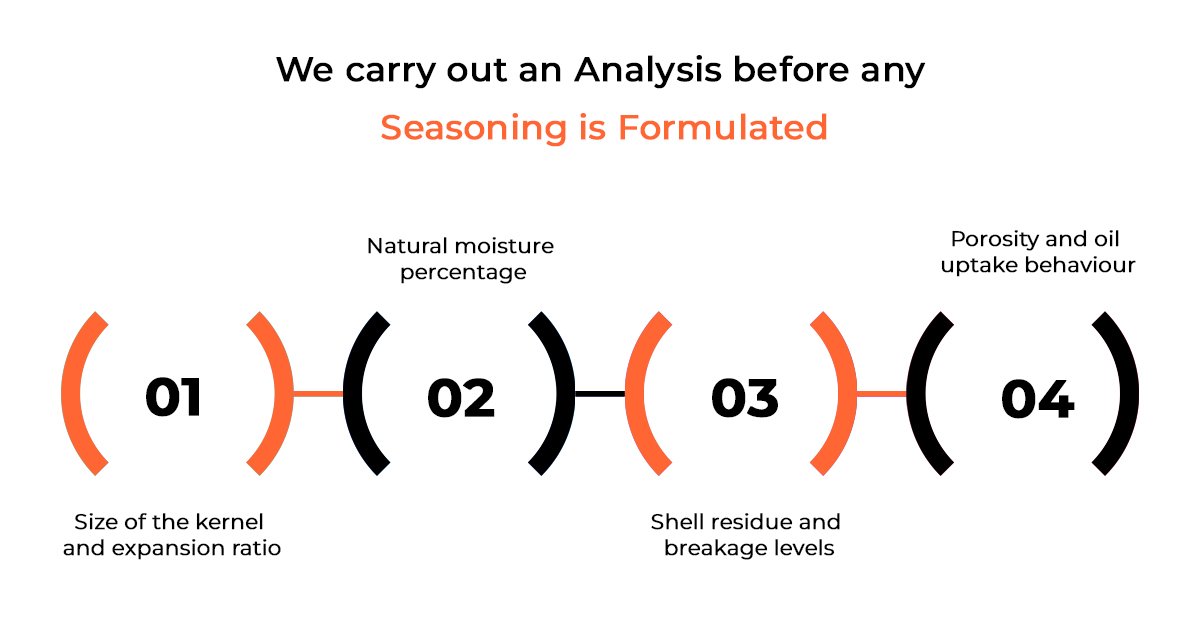

To formulate, the first step is to have a deep understanding of the makhana raw material itself. Fox nuts vary greatly in size, density, and moisture due to the different sources and harvest conditions.

Commercial formulation mainly focuses on:

- Uniform kernel size

- Low percentage of broken kernels

- Controlled natural moisture content

One of the most frequent causes of uneven roasting and texture failure is the inconsistency of raw materials.

Stage 2: Cleaning and Sorting

Before roasting, makhana must be very clean and well graded. Dust, stones, shell residues, and broken kernels negatively affect roasting uniformity and seasoning effectiveness.

The step ensures:

- Consistent heat transfer

- Reduced seasoning loss

- Better visual quality in the final pack

Stage 3: Primary Dry Roasting

Crunch development in dry roasting runs on the foundation. The goal here is to reduce the internal moisture without damaging the kernel’s structure.

Key control includes:

- Roasting temperature

- Time, temperature balance

- Batch versus continuous roasting suitability

If a dry roast is not properly done, the makhana becomes chewy, blistered unevenly, or moisture is still retained, which leads to a shorter shelf life.

Stage 4: Oil Roasting or Tumble Roasting

Contrary to what people commonly think, roasted makhana snacks are not free of oil. A controlled fat system is a must for flavour release and seasoning adhesion.

This is the phase where the recipe sets out:

- Type of oil used

- Method of oil application

- Oil percentage required for texture and stability

If there is less oil, the seasoning will fall out. Too much oil causes quicker rancidity, and therefore, the shelf life will be shorter.

Stage 5: Seasoning Preparation

Seasoning roasted makhana is actually a technical operation. Due to its being light and porous, the seasoning method for makhana should be stable and easily processed.

A commercial seasoning formulation takes into account:

- Salt solubility

- Spice particle size

- Heat stability

- Oil compatibility

While home-style masalas may get burned quite easily, commercial blends are made in such a way that roasting, tumbling, and extended storage won’t make them burn or turn bitter.

Stage 6: Masala Application

Formulation challenge applying seasoning evenly without kernel damage is great.

This step emphasises:

- Controlled tumbling speeds

- Staged seasoning addition

- Ways to prevent breakage and dust

The desired result is a uniformly coated product that looks full, clean, and premium in the pack.

Stage 7: Secondary Roasting or Setting

Secondary roasting seals in crunch and flavour. It stabilises the oil and seasoning on the surface and also gets rid of residual moisture.

There might be a considerable effect on the retention of crunch during the shelf life, even if only a very small moisture variation takes place at this stage.

Stage 8: Cooling and Stabilisation

After roasting, the hot makhana must be cooled immediately and in a controlled manner. If cooling is not done properly, condensation will occur, and that is one of the main reasons for the loss of texture.

This process is to preserve the crunch that is formed during roasting.

Stage 9: Quality Evaluation

The evaluation of a batch includes:

- Taste balance

- Crunch consistency

- Oil percentage

- Seasoning distribution

Stage 10: Packaging and Shelf-Life Alignment

Shelf life is quite a part of the recipe; it is not really something that can be fixed afterwards.

The formulation of the roasted makhana recipe is in alignment with:

- Packaging material selection

- Oxygen and moisture control

- Nitrogen flushing is required

This will make sure that the product will stay fresh and the crunch will be maintained during the entire shelf life.

Why Roasted Makhana Recipe Formulation Requires R&D

Roasted makhana is quite easy to get spoiled by moisture and careless handling. A slight change of even 0.5% in moisture can lead to a change in the sense of crunch and shorten the shelf life.

For this reason, the development of the roasted makhana snack should be considered as a food product development, not cooking. A structured R&D means that the recipe can be turned from pilot batches to commercial production without a loss of quality.

Commercial Perspective for Brands

When it comes to brands starting or growing in the makhana category, a properly formulated roasted makhana snack recipe will have a direct influence on:

- Customer loyalty

- Brand identification

- Distributor belief

- Production efficiency

Marketing alone cannot fix an unstable recipe.

Foodsure Achievements in Makhana Category

Foodsure has been fortunate to assist several Indian snack brands in product development and scale-up of their makhana recipes, such as:

- Makhana snack lines that focus on value

- Premium masala makhana variants

- Healthy & low oil formulations

- Private, label & startup brands

Final Note

The appearance of roasted makhana is simple, but the formation of a reliable, scalable snack around it is a challenge that requires precision at every stage. Finished products are a combination of perfectly controlled roasting, engineered seasoning systems, texture management, and shelf life planning.

At Foodsure, we take the roasted makhana snack recipe formulation as a full product strategy. We are consistent, scalable, and on the way to brand success.

When done right, roasted makhana does not just crunch, it performs.

Develop your Own Makhana Recipe

Foodsure helps founders eliminate early-stage risks by aligning formulation, manufacturing, and compliance into one structured development system.

Trusted by D2C founders and FMCG brands across India

FAQ’s (Frequently Asked Questions)

What is the roasted makhana recipe formulation?

It is a well-organised method of crafting a crispy, flavour-stable makhana snack by means of controlled roasting, seasoning systems, and shelf-life planning for commercial consistency.

Why is professional formulation important for roasted makhana snacks?

For coated makhana, this assures uniformity in roasting, stable crunch, right flavour coating, and consistent quality through all production batches.

What makes makhana distinct from other roasted snacks?

Makhana’s porous, low-fat structure makes it very sensitive to moisture and processing, requiring a specialised food formulation approach.

What oils are used most in roasted makhana recipe formulation?

Only very small amounts of neutral, cold-pressed, or functional oils are used to increase mouthfeel and to help the seasoning stick.

How are you ensuring that the roasted makhana has the crunchiness factor?

Crunch is ensured by a very careful monitoring of moisture, roasting conditions, fat balance, cooling stages, and even packaging.

Is it possible to produce roasted makhana as a clean-label snack?

Absolutely, it can be developed using a few ingredients and clean-label seasonings without affecting taste, texture, or shelf life.

What is the expiry time for a properly formulated roasted makhana snack?

Using proper formulation and packaging, roasted makhana can last for 6 to 9 months while retaining its quality.

Which flavours work best for roasted makhana snacks?

Masala, peri-peri, herb blends, cheese-style seasonings, and mild sweet-spice profiles work best when adapted to makhana’s structure.

Is the roasted makhana recipe formulation scalable for large production?

Yes, professional formulations are specifically created to ensure the same quality across both batch and continuous production systems.

What are the common mistakes in roasted makhana snack development?

The most common mistakes consist of uneven roasting, poor control of oil, weak adhesion of seasoning, mishandling of moisture, and testing only at the kitchen scale.