Roasted makhana appears to be a perfect snack option for venturing into a business. It possesses various characteristics that classify it as a healthy snack business, such as being light, organic, and already having a good consumer base. Most of the companies launch the product without any doubts, and the product gains initial support and even feedback is given. Orders start flowing in, distributors show interest, everything feels right, and then the roasted makhana scale-up begins.

That is the point where most roasted makhana brands quietly struggle or disappear. At our company, we have been supporting various snack brands and snack manufacturer teams from behind the scenes and have witnessed this scenario over and over again. The product is delicious when made in small batches, but as soon as the volumes increase, the consistency of the product is lost, the costs get out of control, the shelf life decreases, and the customer complaints come.

The failure is not because makhana is an unprofitable category. It happens because roasted makhana scale-up is far more complicated than most founders anticipate.

The Myth: “If It Works at Small Scale, It Will Work at Big Scale”

In the production of snacks, this is the biggest wrong assumption. A lot of roasted makhana manufacturers use the recipe from a kitchen that was made under perfect conditions. But large-scale production brings up new factors that home tests never encounter: differences in equipment, variations in raw materials, inconsistencies in operators, and longer supply chains.

The production of roasted makhana scale-up fails at a large scale when the brands consider scaling a volume problem and not a formulation and process problem. Scaling is not simply multiplying a recipe; it demands recreating it.

Problem 1: Ignoring Raw Makhana Variability

It’s quite uncommon that a batch of makhana is identical to the previous one. Initially, small businesses usually get their supplies from one vendor or a single region only. As the healthy snack business grows, the sourcing becomes more diverse. Factors like kernel size, density, moisture content, and porosity start to differ significantly.

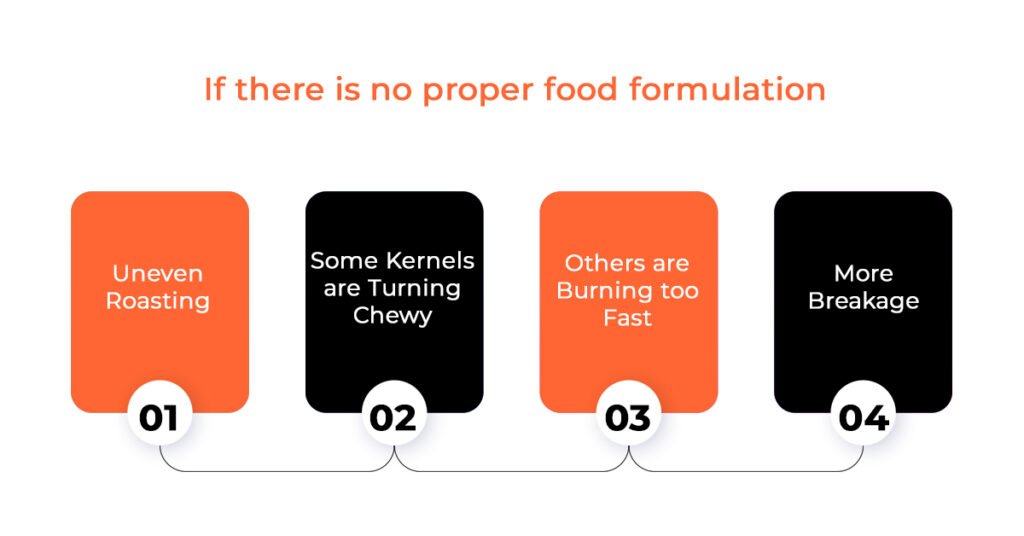

If there is no proper food formulation, it results in:

- Uneven roasting

- Some kernels are turning chewy

- Others are burning too fast

- More breakage

Most brands that sell roasted makhana don’t realise how sensitive makhana is to changes in the raw materials. This variation should be considered during the food product development. If it is not taken care of, the problems come out immediately, roasted makhana scale up.

Problem 2: Roasting Equipment Changes Everything

A small oven or a frying pan behaves totally differently from a big industrial machine. Larger machines alter the heat distribution, cooling, batch thickness, and time of product finishing. The roast profile that gave perfect crunch before may now cause over-drying or under-roasting of the product.

This is the point where the roasted makhana scale-up usually fails. Companies frequently purchase larger machines but do not change the process at all. They think that the equipment will eventually understand it. Professional food product development considers roasting a system rather than a step. Without recalibration, consistency in texture becomes impossible for any serious snack manufacturer.

Problem 3: Fat and Seasoning Stop Behaving the Same

At a small scale, seasoning sticks perfectly and at a large scale, it does not stick at all. Makhana is a challenging product because of its porous surface. Depending on the oil application, seasoning may either come off or form lumps. Unstable coating results in neutral-flavoured packages on one end and extremely flavoured ones on the other.

Numerous brands of roasted makhana confronted this issue too late, in fact, because their seasoning system does not support roasted makhana. In structured food formulation, oil percentage, application method, seasoning particle size, and mixing speed are all designed to work harmoniously. Neglecting this integration is one of the most critical reason scale up fail in the healthy snack business.

Problem 4: Crunch Loss Over Time

For me, this one ranks as an extremely painful failure. The product comes out of the factory perfectly crunchy, but by the time it gets to the consumer, it is soft. The texture is slowly destroyed due to moisture migration, oxygen exposure, and fat imbalance.

In small volumes, this problem is usually unnoticed because the products move quickly. During roasted makhana scale-up, the volume is increased, inventory stays longer, travels farther, and is exposed to different climates.

If shelf life engineering is not accounted for during food product development, then crunch loss is bound to happen. And consumers won’t complain nicely; they just don’t reorder.

Problem 5: Packaging Is Treated as an Afterthought

Packaging is not just a pretty cover; it’s part of the product. The majority of roasted makhana manufacturers select their packaging mainly depending on cost or appearance. Nevertheless, the makhana plant requires a certain barrier to moisture and oxygen to survive.

Brands often discover during the roasted makhana scale-up that their packaging cannot fulfil the product protection. It is costly and inconvenient to change the packaging at such a late stage. In commercial food formulation, the testing of the new product’s compatibility with its packaging is done in conjunction with the product, not after it has been launched.

Problem 6: Cost Explosion at Higher Volumes

Scaling is basically the process of producing a larger volume of goods to reduce the cost per unit. For many makhana brands, scaling does the opposite.

Common reasons include:

- Higher oil absorption due to poor control

- Increased wastage from breakage

- More rejected batches

- Inconsistent seasoning losses

Brands without data, driven by food product development, go after volume at the cost of margin. Eventually, the business model ceases to make sense. This is one of the silent killers of the roasted makhana scale-up for emerging snack manufacturer operations.

Problem 7: Lack of Process Documentation

Small groups trust their gut feelings, and the big groups need to have established procedures.

With an increase in production, several workers do roasting, seasoning, cooling and packing. In the absence of documented controls, the quality of products is determined by the person who is on duty that day.

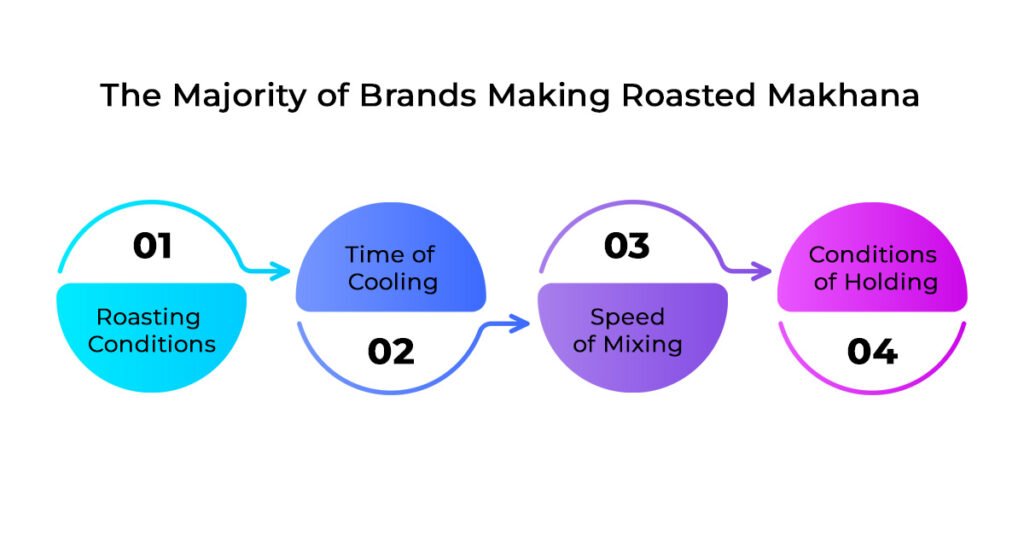

The majority of brands making roasted makhana do not keep records regarding:

- Roasting conditions

- Time of cooling

- Speed of mixing

- Conditions of holding

Once this discipline is not followed, there will be no consistency. Professional food formulation is about documentation as much as it is about the ingredients.

Problem 8: Regulatory and Labelling Oversights

When things get bigger, they also get more closely examined. It claims that at a small scale, one could barely notice, but later on, it can be the reason for compliance issues. Nutritional values naturally change a bit due to processing. Ingredient declarations become not quite accurate.

During the development of a food product, regulatory agreement should be a part of the plan from the very beginning. A lot of roasted makhana scale-up brands treat it as something to fix after the launch, which results in a very expensive correction or market withdrawal.

Problem 9: No Buffer for Distribution Stress

Markets that are real, in fact, are not soft to the product. The products also undergo heat, humidity, pressure from stacking, and transport delays. What comes out of the production line may not be the same as what will survive the supply chain.

Roasted makhana scale-up fails when brands don’t simulate real distribution conditions. A formulation that works only in ideal storage is not market-ready. That’s why seasoned food formulation is the key here; it not only figures out the abuse factor but also gets the best possible perfection.

Why Some Brands Do Scale Successfully

The ones that are victorious do not have better fortune, but better readiness. They treat roasted makhana as a Wonder Product, not just a healthy snack. They devote an already large portion of their resources to a well-choreographed food product development. They complicate their formulation for the purpose of being able to produce large quantities.

They put difficult inquiries before themselves before the market compels them to.

Our Perspective

We don’t consider scale-up as a mere operational task at our company. We treat it as a problem of formulation. Roasted makhana scale-up works only when all the processes, namely, roasting science, flavour systems, texture control, packaging, and cost models, are designed together. If any one link is weak, the entire chain breaks.

We have witnessed the promising roasted makhana brands not getting any further because they were not built to grow. The demand was there, but it was never fulfilled.

Final Thoughts

Roasted makhana is a high-potential category in the healthy snack business, but it rewards discipline, not shortcuts. If your product is following the growth path, the question is not “Can we sell more?” The real question is “Is our formulation ready for roasted makhana scale-up?” Because in this category, success is not determined at launch. It is determined at scale. And that is the point where either most brands grow up or die out.

Frequently Asked Questions

What are the reasons behind the failure of most roasted makhana brands at the time of scaling up?

The small-batch recipe is not scaled up to the larger equipment, raw materials, and supply chain’s advantages.

What is the major factor in scaling up roasted makhana?

The change in the roasting and seasoning behaviour at the large scale causes the difficulty in keeping the crunch and flavour of the whole product..

How does food formulation play a role in makhana scale-up?

Proper food formulation allows one to have control over the variability of the ingredients, the moisture, the oil absorption, and the seasoning adhesion, which are all necessary for scalable production.

Can you give a recipe for home-style roasted makhana that can be made in large quantities for commercial use?

Such an occurrence is occasional because home-like recipes lack process control, shelf-life stability, and cost predictability, which are essential for the mass production of commercial products.

What are the factors behind scaling up roasted makhana losing its crunch?

Loss of crunch is caused by improper moisture control, incorrect fat levels, packaging issues, and cooling and resting stages not long enough.

How important is the roasting equipment to the production scale-up?

Roasting equipment is very important since the variations in the heat and airflow directly impact the drying, texturing, and overall product consistency.

What is the main factor of packaging in the roasting of makhana scaling?

The packaging not only decides the moisture and oxygen protection, but if the barrier properties are not good, even the best of the product can be compromised.

How can roasted makhana brands maintain their costs during scaling up?

Cost is controlled through the best formulation, less waste, process stability, and the use of ingredients and packaging that are efficient in scale.

At what point should brands make an investment in professional food product development?

Before the scaling starts, as otherwise it will result in higher losses, recalls, and costly reformulation.

How can brands increase their probability of success in scaling?

By considering scaling a formulation and process challenge, and creating systems that guarantee consistency and endurance.