Most food items are initially delicious at tasting sessions. The taste is well-balanced, the texture is just right, and the in-house sensory panel gives a thumbs-up. However, after a few weeks or months, the product does not pass shelf life testing due to shelf life failure food issues. It is a situation that occurs far more often than most food brands anticipate.

It is essential for food startups, MSMEs, and established manufacturers working on food formulation and food product development to understand shelf-life failure issues. A product that impresses in terms of sensory attributes but fails on shelf life can cause wastage, recalls, delayed launches, and a loss of market trust.

In this blog, we discuss why products that have sensory approval fail shelf life tests, what usually happens in the background, and how the brands can avoid shelf life test failures during food product development.

You May Also Like: Best Food Business Ideas

Sensory Approval vs Shelf Life: Why They Are Different

Sensory approval is concerned with the evaluation of a product’s taste, smell, appearance, and texture at a particular moment, mainly shortly after the product is made. Conversely, shelf life testing determines how a product continues to perform over time based on the conditions of storage and distribution.

A product can receive a perfect score in sensory tests and still be a shelf life failure, or even become a total shelf life test failure due to very slow chemical, microbial, or physical changes that are not detectable immediately.

Basically,

- Sensory testing answers: Is the product good right now?

- Shelf life testing answers: Will the product be safe, stable, and acceptable after some time?

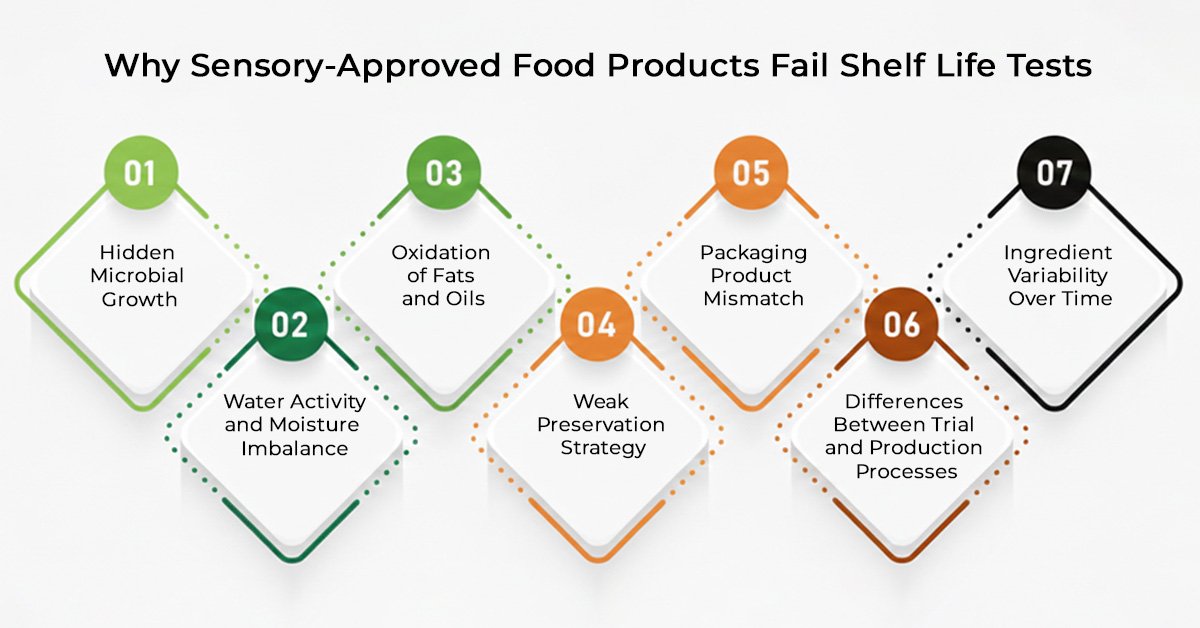

Why Sensory-Approved Food Products Fail Shelf Life Tests

1. Hidden Microbial Growth

At first, many food products look stable, but over time, they allow microbes to grow gradually. Also, even acidic, cooked, or low-moisture products can be spoiled if there is no proper formulation, processing, or hygiene control.

Most shelf-life failures in food happen because microbial risks are assumed instead of properly tested and validated.

2. Water Activity and Moisture Imbalance

If only on paper, moisture control may look satisfactory; however, an uneven water activity inside the product can result in:

- Breaking of the texture

- The growth of mould

- The formation of clumps or sogginess

Initially, the changes in products are missed by the panellists, but the change in product characteristics over time is exposed by shelf-life testing.

3. Oxidation of Fats and Oils

Oils, nuts, seeds, or dairy fats in products lead to oxidation. Rancidity develops slowly and may not be obvious during the early sensory evaluation.

If proper antioxidants and protective packaging are not provided, oxidation will be the main reason for the failure of the shelf life of food products.

4. Weak Preservation Strategy

A product might be delicious but still lack adequate long-term preservation. Usually, preservative systems that are just for taste compatibility fail to protect the product throughout its intended shelf life.

Preservation has to be stable not only by immediate sensory acceptance but also through time.

5. Packaging-Product Mismatch

Packaging is one of the most important factors in determining the shelf life of a product. If the packaging materials used are not compatible with each other, they will allow oxygen, moisture, or light to enter, and thus, the product will spoil much faster.

It is quite possible that even a product that has been formulated excellently will not pass the shelf life testing if the selection of packaging is poor.

6. Differences Between Trial and Production Processes

Shelf, life failures are a common occurrence when the process used during the trials is not exactly repeated during production. Variation, even to a minor extent, in heating, cooling, filling, or sealing can have a significant impact on stability.

The aforementioned discrepancy is an unadvertised but very frequent cause of shelf life failure in the case of food.

7. Ingredient Variability Over Time

Sometimes, the quality of the ingredients varies due to changes in suppliers or different batches. Slight differences in moisture, quality of fat, or microbial load may/may not affect the taste at first instance, but can reduce the shelf life.

In the absence of firm ingredient specs, it becomes very challenging to keep shelf life consistency.

How Shelf Life Failure Impacts Food Brands

Shelf life failure has a great impact not only on the product but also on other issues. It usually results in:

- Increase in wastage and rework

- Launches are getting delayed or cancelled

- Risk of non-compliance with regulations

- Retailer refusals

- Loss of consumer confidence

It is much cheaper to start preventing shelf life failure early rather than to solve the issues

How to Prevent Shelf Life Failure in Food Products

The elimination of shelf life failure food issues necessitates a well-structured, scientifically grounded approach that incorporates food formulation and food product development right from the outset.

Key Prevention Strategies

| Prevention Steps | How It Helps Prevent Shelf-Life Failure |

|---|---|

| Design Shelf Life During Formulation | Shelf life is planned from day one by considering water activity, pH, fat stability, and preservation systems—not just taste. |

| Validate Preservation Systems | Preservatives, thermal processing, and hurdle technologies are tested and validated rather than assumed to work. |

| Align Packaging With Product Needs | Packaging is chosen based on oxygen, moisture, and light barrier requirements instead of cost alone. |

| Conduct Realistic Shelf-Life Testing | Testing simulates real storage, transport, and distribution conditions rather than relying only on accelerated tests. |

| Maintain Process Consistency | Production closely matches trial conditions to avoid stability changes caused by process deviations. |

Why Shelf-Life Planning Must Be Part of Food Product Development

Shelf life is something that cannot be considered as an afterthought in product development. It has to be a part of the formulation, processing, and packaging decisions from the very beginning.

Brands that focus on shelf, life planning cut down on trial and error, save on development costs, and increase their chances of market success.

Role of Food Product Development Experts

Experienced food product development partners play a crucial role in identifying shelf-life risk factors early on. They bring together formulation science, processing knowledge, packaging expertise, and testing protocols into a single, well-connected strategy.

This fusion of expertise reduces the likelihood of shelf life failure, minimises the risk of shelf life test failure, and facilitates efficient and scalable product launches of sensory-approved products.

Final Thoughts

Sensory approval is indeed very important; however, it cannot solely guarantee the success of a product. Many food products that taste great at first are still doomed to failure because the stability, processing or packaging aspects get them overlooked.

Brands can make products that deliver great taste at first and still be safe, stable and reliable throughout their intended shelf life by identifying shelf life failure food risks at an early stage. Making shelf life planning a part of food product development can help in cutting down losses, preventing rework and facilitating long-term growth.

Want to create a food product that is not only liked by the testers but also performs well in the market?

Before expensive problems become a reality, consult with our specialists to discuss your formulation, shelf life strategy, and development roadmap.

Avoid Shelf Life Failure Before It Impacts Product Quality

Foodsure helps food brands prevent shelf life failure, reduce quality loss, and ensure product stability, backed by formulation expertise and shelf life science.

Explore Product Development Services

Foodsure helps food brands build FSSAI approved food labels that meet regulations, avoid errors, and support smooth approvals — backed by regulatory expertise and labelling science.

FAQs

Why do sensory-approved products sometimes fail to meet shelf life requirements?

Just because a product is taste-approved doesn’t necessarily mean it will be free from microbial, chemical, or packaging-related issues during its time on the shelf.

What accounts for the majority of shelf life test failures in food?

Most of the time, the failure can be attributed to the food not being preserved correctly and the mismatch of packaging.

Is food formulation a factor in shelf life failure?

Definitely, improper formulation of a product can cause instability, oxidation, or growth of microorganisms.

During what stage of food product development should shelf life be taken into consideration?

One should think about shelf life right from the stage of formulation and not when the product is already finalised.

Are preservatives capable of preventing shelf life failure and food-related issues always?

No, the effectiveness of preservatives is only ensured when they are used together with appropriate processing and packaging.